A team at MIT has unveiled a material that could transform how electric vehicle (EV) batteries are recycled, potentially easing one of the industry’s most pressing environmental challenges.

The researchers have created a self-assembling electrolyte that, after powering a solid-state battery, can break apart within minutes when submerged in an organic solvent. This process allows electrodes and other components to separate naturally, eliminating the need for energy-intensive shredding and chemical treatments that dominate recycling today.

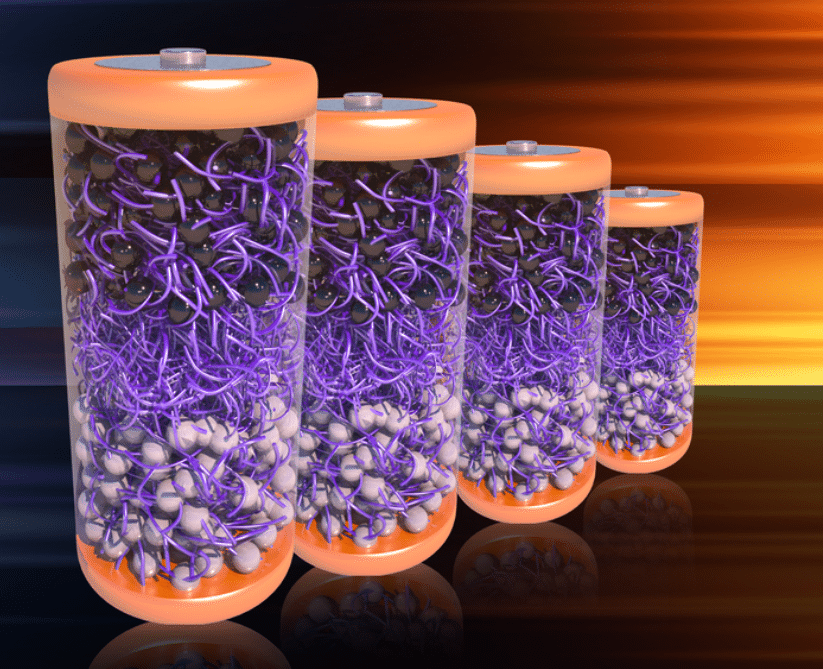

The study demonstrates that the material, based on aramid amphiphiles (AAs) with polyethylene glycol (PEG) components, can both conduct lithium ions and form strong Kevlar-like nanoribbons. These nanoribbons provide mechanical stability while enabling ion transport across a solid-state cell. Importantly, when the battery reaches its end of life, the electrolyte dissolves like “cotton candy in water,” allowing components to be recovered more easily.

The team—comprising Cho, PhD candidate Cole Fincher, Ty Christoff-Tempesta PhD ’22, Professors Yet-Ming Chiang and Julia Ortony, along with collaborators Xiaobing Zuo and Guillaume Lamour—tested the material in a prototype battery using lithium iron phosphate and lithium titanium oxide electrodes. While it successfully transported lithium ions, performance was hampered by polarization effects during rapid charging and discharging. The researchers emphasize the material is an early proof of concept, envisioning it as one layer in future electrolytes rather than a complete replacement.

Beyond performance optimization, the recyclable design could play a strategic role in securing lithium supplies. With EV adoption accelerating, reusing lithium from old batteries could offset demand pressures and reduce reliance on mining.Funded by the U.S. Department of Energy and the National Science Foundation, the work represents a paradigm shift: batteries engineered not just for performance, but for end-of-life recovery. If integrated into next-generation designs, such self-assembling electrolytes could help scale EV adoption sustainably—turning today’s waste problem into tomorrow’s supply solution.

“Designing batteries for recyclability from the beginning is a new approach,” said lead author Yukio Cho PhD ’23. “Instead of making high-performing but hard-to-recycle systems, we start with recyclable materials and adapt them to battery needs.”