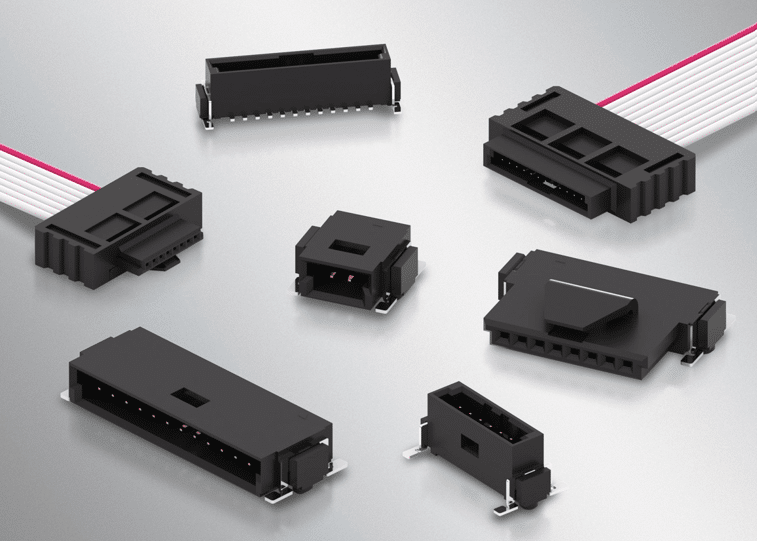

Featuring a 1.27mm pitch and a variety of pin-count options, the latest additions provide improved assembly, secure mating, and high reliability under challenging conditions.

Harwin has introduced a significant expansion to its Kontrol range of industrial board-to-board interconnects (BBi), adding single row connectors and cables to its established 1.27mm pitch (0.05″) series. Designed to bridge the gap between premium connectors and traditional pin header/socket solutions, this new launch enhances design flexibility for engineers tackling demanding applications.

The latest additions include 49 new products: 21 surface-mount technology (SMT) connectors and 28 double-ended cable assemblies. The expanded lineup offers pin-count options of 2, 3, 4, 6, 8, 10, and 12, catering to diverse application needs

High-Performance Specifications include:

.

- 1.2A current rating per contact

- 25mΩ contact resistance

- Durable for up to 500 mating cycles

- Operates in temperatures from -55°C to +125°C (board-to-board)

- Withstands vibration forces of 20 G for up to 12 hours

The new single-row SMT connectors come in vertical (male) and horizontal (male and female) mounting options. These connectors feature full shrouding and recessed contacts, safeguarding pins from damage. Assembly improvements include polarization to prevent mis-mating and tolerance for up to 0.075mm linear and 4.3° angular misalignment.

With a latched design enabling tool-free mating and unmating, surface-mount tabs ensure enhanced retention force on the PCB. Additional location pegs assist with accurate placement during assembly and soldering.Complementing the connectors, the male and female double-ended cable assemblies feature in-line connectors and UL-specification 26 AWG ribbon cables, available in 150mm and 300mm lengths. These assemblies incorporate shrouding, latches, and polarization, ensuring secure and reliable connections.

John Feaster, BBi Product Manager at Harwin, commented: “Our new single-row Kontrol connectors and cables provide designers with greater flexibility for creating robust designs that meet today’s stringent demands and future challenges.”

Learn more by clicking here.