Artificial tendons make muscle-powered robots stronger and faster. They can last longer and work in tricky or dangerous places.

Biohybrid robots often face a key limitation: their muscle-powered motion is weak and slow. Soft muscle tissue is difficult to attach to rigid skeletons efficiently, and much of the force is lost at connection points. The tissue can tear or detach, leaving robots with limited strength and restricting their ability to perform tasks that require speed, durability, or repeated operation.

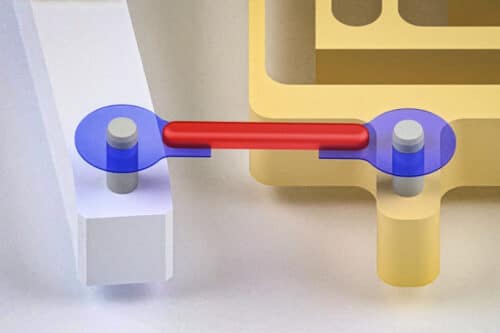

Engineers at MIT have addressed this challenge by adding artificial tendons to biohybrid designs. These hydrogel tendons bridge the mechanical gap between soft muscle and rigid skeletons, efficiently transmitting force to moving parts. In experiments, a robotic gripper equipped with a muscle-tendon unit pinched three times faster and with 30 times more force than a gripper powered by muscle alone. The system maintained this performance over thousands of contraction cycles while requiring far less muscle tissue, dramatically increasing the power-to-weight ratio and durability.

Muscle-based actuators also offer unique benefits. Unlike traditional robotic motors, muscles can grow stronger with use and naturally heal when damaged. These qualities make them ideal for robots operating in hazardous or remote environments, where adaptability and self-repair are crucial. Potential applications include miniature surgical assistants performing delicate procedures inside the body, small construction robots, or machines tackling unexpected tasks in unpredictable environments.

The MIT team’s approach combines lab-grown muscle tissue with synthetic skeletons, using tendons to form a “muscle-tendon-skeleton” system. By modeling the components as interconnected springs, researchers determined the optimal stiffness for the hydrogel tendons, ensuring efficient force transfer and protecting the soft tissue from tearing. This architecture also allows modularity, meaning the design could be adapted to various biohybrid robots, from crawlers and walkers to swimmers and grippers.

These advances bring biohybrid robots closer to practical use outside the lab. Tendon-assisted muscle actuators can move larger structures safely and reliably while maintaining repeated performance. MIT researchers are now developing protective casings and additional components to enable these robots to function effectively in real-world settings, bridging the gap between biological and robotic capabilities.