Silhouette-based platform delivers sub-micron repeatability, 25 μs exposure and distortion-free measurement across the entire field of view.

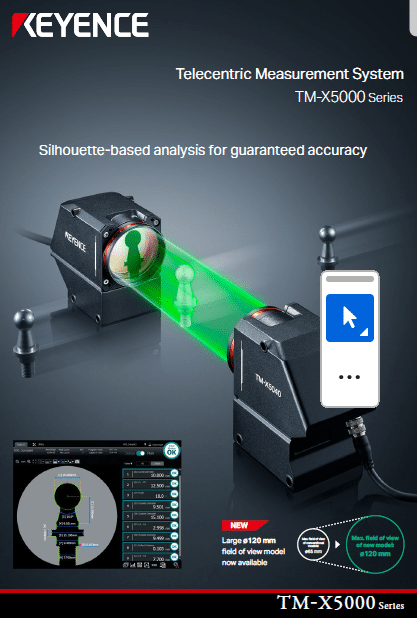

KEYENCE has expanded its TM-X5000 Series with a new ultra-wide-field sensor head offering a 120 mm field of view, targeting high-speed inline dimensional inspection across larger components.

The key features are:

- Dual telecentric optical system with 0.0001° telecentricity (typical)

- Ultra-wide 120 mm field of view option

- 25 μs minimum exposure; sampling cycles down to 3 ms

- Repeatability down to ±0.03 μm; position accuracy to ±0.2 μm

- Up to 100 simultaneous measurement tools with inline defect detection

The latest addition increases the maximum measurement area from 65 mm to 120 mm while maintaining sub-micron repeatability. Designed for outer diameter, gap, width and profile inspection, the system combines dual telecentric optics with silhouette-based analysis to deliver stable measurements regardless of material type including transparent and reflective targets.

At the core of the platform is a dual telecentric optical system with lenses in both transmitter and receiver. By using collimated green LED illumination and a high-resolution CMOS sensor, the system captures sharp edge silhouettes even when targets shift within the field of view. Telecentricity of 0.0001° (typical) helps minimize size variation due to misalignment.

Exposure times as short as 25 μs up to 40 times faster than conventional models allow blur-free measurement of fast-moving or rotating parts. The system supports sampling cycles as fast as 3 ms, enabling true inline inspection without slowing production lines.

Measurement position accuracy is specified up to ±0.2 μm in high-accuracy areas, with repeatability down to ±0.03 μm depending on the selected head. Distortion-free optics and sub-pixel processing divide each pixel into more than 100 sub-pixels to maintain accuracy across the full field of view, reducing edge-detection variation.

The controller supports up to two sensor heads and up to 100 measurement tools per head, including GD&T, pitch, runout and master comparison functions. Integrated abnormality detection enables simultaneous dimensional measurement and detection of burrs, chips or foreign particles. With IP64-rated heads, optional fieldbus units including EtherNet/IP, PROFINET and EtherCAT, and CAD import capability for rapid program creation, the system is positioned as an all-in-one platform for automotive, electronics, medical and precision manufacturing environments.