Smaller thermal sensors show clearer images and help portable devices detect and recognize things faster.

High-resolution thermal imaging is often limited by sensor size, weight, and pixel density. Designers struggle to fit more detail into compact systems without compromising detection performance, especially for handheld, mobile, or airborne devices. Traditional 12 µm sensors deliver acceptable thermal performance but require larger modules, making devices heavier and bulkier, which is a challenge for riflescopes, monoculars, drones, and other portable thermal imagers. Achieving long-range detection, recognition, and identification (DRI) in a small form factor has been a persistent problem for both commercial and defense applications.

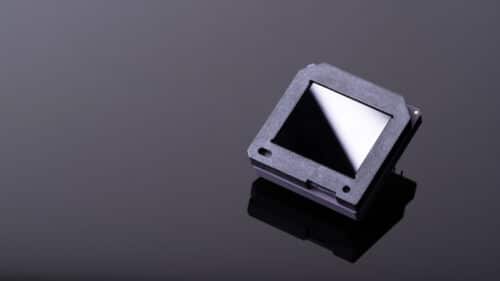

LYNRED’s YOCTO family addresses these constraints by using an 8.5 µm pixel pitch microbolometer. The YOCTO1024 model fits 2.5 times more pixels into the same area as a standard VGA 12 µm sensor, delivering XGA resolution while keeping the module ultra-compact. This increase in pixel density allows sharper, more detailed images and improves DRI performance by up to 40%, roughly equivalent to a 1.4× magnification, without increasing sensor size or weight.

Built on VOx technology optimized for the LWIR spectrum, YOCTO1024 measures just 18×18×4.85 mm³, reducing the footprint by up to 40% compared to standard XGA 12 µm sensors. For system designers, this means smaller, lighter packages can be built without sacrificing image quality or thermal sensitivity, enabling more ergonomic and versatile devices for hunting, leisure, and professional surveillance applications.

YOCTO meets growing market demand for compact, high-performance thermal modules. It supports handheld thermal imagers, weapon sights, drones, fixed observation systems, and optical devices such as binoculars and riflescopes. By combining compactness, high resolution, and scalable production, the platform makes it easier for integrators to deliver devices that meet user expectations for portability and long-range detection.

The company maintains full control over the entire detector design and manufacturing process in Europe, ensuring consistent quality and performance. YOCTO complements the existing 12 µm ATTO line, giving engineers flexibility to select the right balance of resolution, footprint, and thermal performance for their applications. A recent expansion of production capacity positions YOCTO as a high-volume, reliable solution for both commercial and defense markets.