Researchers have developed an easy way to create an electronic network inside a polymer using an acoustic field to connect liquid metal dots.

Portable devices and wearables are being developed with a focus of ease of use to customers. Recent advances in device scaling has led researchers to expand the application window for these instruments. For example, Sensors Embroidered Into Threads Of Clothing Monitors Breathing.

Researchers at the Korea Advanced Institute of Science and Technology, in coordination with the Institute for Basic Science, both in the Republic of Korea, have found an easy way to create an electronic network inside a polymer. They used an acoustic field to connect liquid metal dots.

Portable devices go through a large amount of stress and strain. Customers demand them to be more flexible and and/or bendable. It is believed such a change would make them fit more easily and naturally in pockets or purses—and they might be more comfortable in the hands, as well.

To do so, the circuits inside them also need to be bendable. This is a problem as such stretchable materials are not categorized as conductive materials. To overcome this problem researchers adapted to the liquid metals. But using liquid metals was a challenge as well, as they react with oxygen, leading to the formation of an oxide skin, which is not conductive.

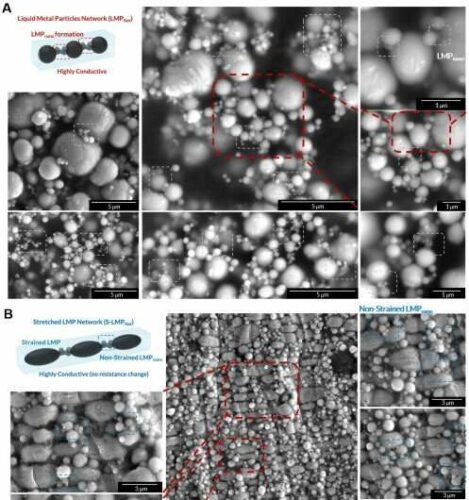

To solve this problem, researchers used an acoustic field to create a bridge between liquid metal drops, which they then embedded in a polymer. The researchers printed gallium-based liquid metal drops onto a surface while also applying an acoustic field. The vibrations from the field led to the formation of mini-drops forming a bridge between the larger drops, which allowed for the formation of a conductive network—and that allowed for the construction of a circuit. After the oxide skin formed, the liquid metal network was embedded inside of a bendable/stretchable polymer.

The result was a circuit that could be both bent and stretched. Testing showed that under strain, the individual beads of liquid metal stretched into oval shapes, allowing the circuit to continue conducting electricity. It is believed such a change would make them fit more easily and naturally in pockets or purses—and they might be more comfortable in the hands, as well.