Automated test systems

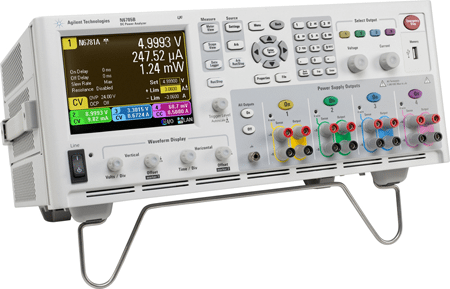

In automobile production, typically, automated test equipment (ATE) are used to achieve high throughput and efficiency. ATE are built using COTS equipment like oscilloscopes, spectrum analysers, DC power analysers, data acquisition systems and switches with a difference that these are interconnected via LAN or GPIB and the software runs the required test routines and hence controls these equipment. A lot of T&M vendors provide modular or synthetic instrumentation, which can be combined to form an ATE depending on the specific requirement.

Jain shares that there are turn-key test solutions for engine control module (ECM) testing which are primarily used in a manufacturing set-up where time (test development, execution and system deployment), cost (capital and integration) and scope (throughput, accuracy and flexibility) are of utmost importance.

“T&M vendors also provide solutions based on the OpenChoice structure, which means customers can easily develop their own software or utilities script for an automation testing mechanism,” adds Sun. Also, “a small number of manufacturers use innovative processes by transmutation of communication technology for verification of mechanical parameters,” says Gautam.

Automotive communication test systems

Electronic control units communicate with each other using some protocol like controller area network (CAN), local interconnect network (LIN), FlexRay, and media-oriented systems transport (MOST) for multimedia and infotainment.

“Debugging and testing this type of network topology can be challenging and time-consuming,” says Sun. Pathak adds, “Due to huge in-vehicle communication and stringent emission norms, it necessitates data logging for a long duration along with the ability to replay the same.”

The popular usage of CAN in automobiles has also prompted the development of a variety of CAN interfacing tools. However, Gautam says, “after the design phase is over, a recursive approach is generally followed by using test and measurement instruments and going back to conduct modifications based on the actual test results until perfect values are physically achieved. No prototype can afford to proceed for further stages of design cycle by completely substituting actual measurements with simulation.”

Jain says, “To test these serial data protocols and hence the communication between various ECUs, an oscilloscope with CAN or LIN decoding and triggering capability is used. Also, one can use a logic analyser to perform timing and state analysis on the bitstreams and command execution.”

ECU: critical to test

The electronic control unit (ECU) is the heart of automotive electronics. It takes care of the engine control, transmission, airbags, antilock braking system, audio system, windows, doors, mirror adjustments, environment control and many other such systems and sub-systems. “It is difficult to prioritise the automotive assemblies in terms of their relative importance because the basic operation of an automobile is completely dependent on coherent operation of all the modules, big or small,” says Gautam.

“Using ECUs to control both essential and non-essential automotive systems is becoming the new industry standard. Based on digital technology, these ECUs require a deeper understanding of complex timing and signal integrity issues,” shares Sun.

Testing of automotive electronics relies heavily on being able to interact with a particular ECU responsible for a particular electronic sub-system. Panikkar says, “Initially, these test systems are used to test prototypes of the ECU in a rapid-control prototyping scenario, where they provide real-world signals to the prototype. They are used for fault insertion and studying the behaviour of the sub-system under varying conditions and limits.” With vehicles incorporating more and more electronics, testing of driver information systems, navigation as well as in-vehicle entertainment systems is also necessary and critical.

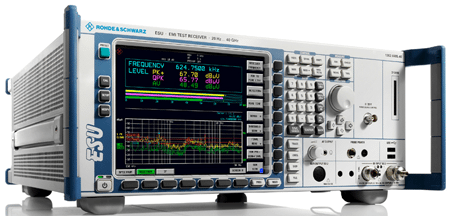

EMI/EMC: a rising concern

The staggering growth of electronics in automobiles has led to a rising concern about electromagnetic compatibility (EMC) and electromagnetic interference (EMI) issues. Telematics, electric power, use of electronic controls in place of mechanical, in-vehicle infotainment, wireless voice and digital communication, active suspension, antilock brake and satellite navigation are some of the functional units that give rise to EMI/EMC issues. T&M vendors are developing new methods, tools and standards for automotive EMC testing.

“For EMI/EMC testing, you require EMI receivers. Apart from this, T&M providers provide antennae, amplifiers, signal generators, power meters and other test transducers required for automotive EMC testing,” says Gautam.

RF testing

Use of radio frequency (RF) interfaces within an automobile for communication, safety and security systems has created the need to develop and measure real-time RF systems that can efficiently monitor vehicle operation and status.