Flexible electronics are already reshaping the present. As innovation accelerates, India is set to lead in scalable, sustainable production. The question is not if but how soon they will redefine our world.

The next generation of technology is flexible. Devices that bend and stretch without compromising performance are transforming healthcare, consumer electronics, and beyond. The most visible example? Foldable smartphones. But the scope of flexible tech extends far beyond that, spanning wearables, healthcare innovations, smart packaging, and much more.

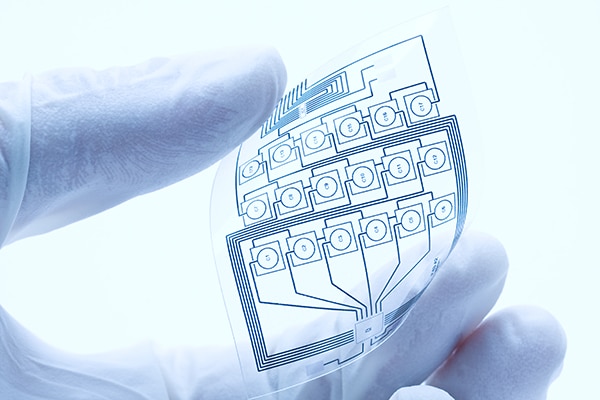

Printable electronics are at the forefront of this revolution, where circuits are printed like ink on paper, creating scalable and cost-effective solutions for a more adaptable future.

How do Printed Electronics Work?

So, what makes printable electronics so special? It all begins with conductive inks, which use nanoparticles of silver, copper, or carbon to create circuits on substrates such as paper, fabric, or flexible plastic. These materials are far more flexible than traditional ones, allowing for electronics that bend and stretch.

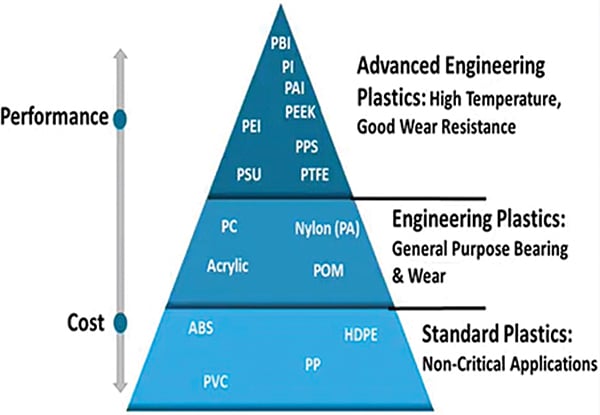

Polymer technology also plays a major role, providing versatile materials that can serve as conductors, semiconductors, or insulators. This flexibility, combined with roll-to-roll printing techniques, helps bring down costs while scaling production, paving the way for mass-produced, adaptable electronics.

Innovations in nanotechnology, including graphene and self-healing polymers, enhance durability and device functionality. Self-healing materials are especially valuable for wearables, which demand resilience for daily use.

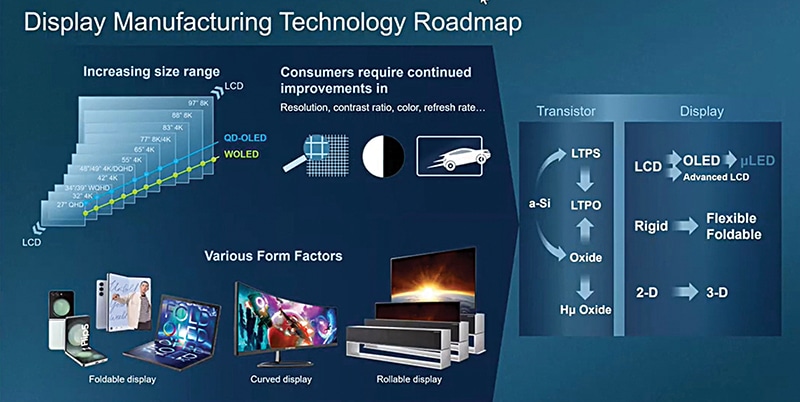

Meanwhile, advancements in thin-film transistors (TFTs) and organic light emitting diodes (OLEDs) improve performance and lower costs, making flexible displays more accessible.

India’s Emerging Leadership in Flexible Electronics

India is quickly positioning itself as a key player in the global flexible electronics market.

Institutions like IIT Kanpur’s National Centre for Flexible Electronics (NCFE) are at the forefront, combining academic research with practical applications.

The country’s robust chemical production base gives it an edge in developing conductive inks and substrates, which are critical for scaling up production.

But there is more to India’s potential than just chemical expertise. The ‘Make in India’ initiative, government support, and private-sector innovation are creating fertile ground for growth.

For example, FlexE at IIT Kanpur is working on prototypes that showcase the broad applications of printable electronics, such as flexible sensors and RFID tags used in healthcare, food safety, and logistics.

The demand for flexible healthcare devices is another compelling reason for India’s involvement. With an ageing population, India’s healthcare sector is primed for disruption, and flexible electronics could revolutionise solutions for chronic disease monitoring, remote care, and senior healthcare.

As India’s population grows and its tech infrastructure improves, the country has the potential to become a global leader in flexible electronics production.

| Advantages Driving Adoption |

| The adoption of additive manufacturing in printable electronics is transforming production, offering significant economic and environmental benefits. This technology is reshaping multiple industries. • Cost efficiency: Additive manufacturing significantly reduces material waste, lowering production costs • Scalability: Rapid prototyping and mass production capabilities make printable electronics ideal for consumer markets • Eco-friendliness: Biodegradable substrates and inks align with the growing emphasis on sustainability As these advantages continue to evolve, additive manufacturing will remain a driving force in revolutionising industries and promoting eco-friendly practices. |

Challenges and Opportunities in Manufacturing

Despite the exciting opportunities, India still faces significant challenges in developing a large-scale electronic printing infrastructure. While India ranks among the top 10 for chemical production, its capabilities in electronic printing lag behind.

This ‘chicken-and-egg’ problem—where industries hesitate to invest in chemical production without reliable printing technologies—remains a hurdle.

However, experts believe that collaboration between academia, industry, and the government is key to overcoming this barrier. By leveraging India’s chemical expertise and developing robust infrastructure for electronic printing, the country can move closer to realising its leadership ambitions.

Flexible displays and OLED technology are among the most promising developments, making electronics lighter, more durable, and cost-effective. India’s advancements could lead to mass-produced, affordable electronics for global consumers.

Healthcare with Personalised Monitoring