From stones to semiconductors, warfare has had a long journey. Missile guidance, hypersonic speeds, and fragile chip supply chains now define precision, power, and military strategy. But how?

Looking back on the history of warfare only reveals how it has evolved with time. From the early use of stones as weapons to the development of spears and arrows, each advancement marked a significant shift in how conflicts were fought. The discovery of explosives proved to be a turning point, spurring the development of cannons and firearms that fundamentally changed the nature of battlefields.

The advent of the Second World War brought aerial warfare to the forefront, with aircraft increasingly used for bombing missions. However, the accuracy of these bombings was often compromised by factors such as wind and atmospheric conditions, leading to the development of the concept of circular error probability (CEP). These limitations prompted the development of guided bombs, significantly improving precision in warfare.

At the same time, aerospace and missile technologies advanced in parallel. Missile technology, initially developed for military purposes, later found applications in the aerospace sector. The underlying mechanics and scientific principles remain consistent, whether a rocket places a satellite into space or a missile delivers a payload to a specific target. Today, missiles form a critical component of modern warfare, combining range, lethality, and stealth to extend the operational reach of armed forces.

The electronic brain of missile technology

Missile technology represents a remarkable achievement of modern engineering. At the core of any missile lies its onboard electronics, which function as its decision-making system and guide its flight path. For a missile to operate effectively, it must continuously determine its position and trajectory through a combination of guidance systems, control mechanisms, propulsion, and complex electronic circuitry.

A delicate balance must be maintained between range, payload, electronics, and total weight to achieve optimal performance across varying operational environments. Missiles are classified according to their role, launch platform, and guidance mechanism. As specialisation increases, so does the complexity of onboard electronics. A typical missile may incorporate between 500 and 600 critical technology components. The evolution of missile systems has closely mirrored advancements in military vehicle technologies, increasing the technical demands placed on designers and analysts.

As missile technology advances, associated vulnerabilities also grow. Every system must address a wide range of considerations, including production processes, transportation, waste handling, information technology infrastructure, documentation, storage, and supply chain management. Climatic conditions further influence operational reliability, as military hardware is required to function across an extensive range of environmental extremes.

Natural threats also pose significant risks. Atmospheric ions and radiation can interfere with onboard electronics, while phenomena such as ion storms or electromagnetic pulse (EMP) events can disrupt or disable missile systems entirely. These risks underline the importance of robust design, extensive testing, and resilience against environmental and electromagnetic challenges.

The dynamics of missile launch

Each missile launch imposes considerable mechanical and aerodynamic stresses on the system. This is analogous to the behaviour of a vehicle at high speed, where maintaining control becomes increasingly complex, as even small steering inputs can result in significant deviations. Similarly, as a missile accelerates, it encounters multiple forces, including drag, thrust, weight, gravitational pull, and lift, all interacting within the operating environment.

At high velocities, even minimal movements can generate substantial gravitational forces (G-forces). These forces exert intense pressure on the missile structure, making a strong external casing essential to protect internal components and ensure structural integrity throughout the flight.

Modern missile development has entered the realm of supersonic and hypersonic speeds, with ongoing efforts to exceed Mach 5. Mach 1 represents the speed of sound, approximately 580 metres per second. At Mach 5, a missile can travel five kilometres in one second. The extreme G-forces generated during such acceleration demand communication and computing systems capable of near real-time mission processing. Transmission, calculation, feedback, and correction must occur with minimal delay. Even a one-degree error can significantly alter a missile’s trajectory. For instance, a one-degree deviation over a distance of one kilometre can result in a miss of approximately 17 metres. In aviation terms, a one-degree error at take-off from Mumbai could redirect an aircraft towards Chennai instead of its intended destination.

The complexity of the Akash missile system

The Akash missile system illustrates the intricate integration required in modern missile programmes. Development involves multiple suppliers, each responsible for specific components such as the airframe, electronics, or radar systems. These contributors are often distributed across different geographical locations, making standardisation essential. A single component failure can compromise the entire system.

The typical service life of a missile is approximately ten years, comparable to the functional lifespan of personal computing devices. However, due to the high costs involved, several countries, including India, continue to operate missile systems well beyond their intended service life, in some cases by as much as 25 years. This extended usage highlights the importance of comprehensive lifecycle management, encompassing storage, pre-launch preparation, operational deployment, and eventual decommissioning.

Decommissioning presents its own challenges, requiring secure handling of sensitive components and careful management of the broader defence ecosystem. In the military supply chain, the primary customer is the nation’s defence forces, and meeting their operational and security requirements remains paramount.

A key dilemma for the military lies in supplier capability. Missile technologies must be lightweight, strong, and adaptable, yet they are expensive and produced in limited volumes. Unlike the Second World War, when mass production of military hardware was common, modern defence manufacturing must balance stock availability with just-in-time production strategies.

The demand for plug-and-play configurations is increasing, as personnel in the field require components that are readily available and quick to assemble. Time sensitivity has become especially critical in contemporary conflicts such as the ongoing war between Russia and Ukraine. The evolving global defence landscape, marked by new collaborations and strategic alliances, reinforces the importance of modular system design that can adapt to changing operational requirements.

The semiconductor supply chain

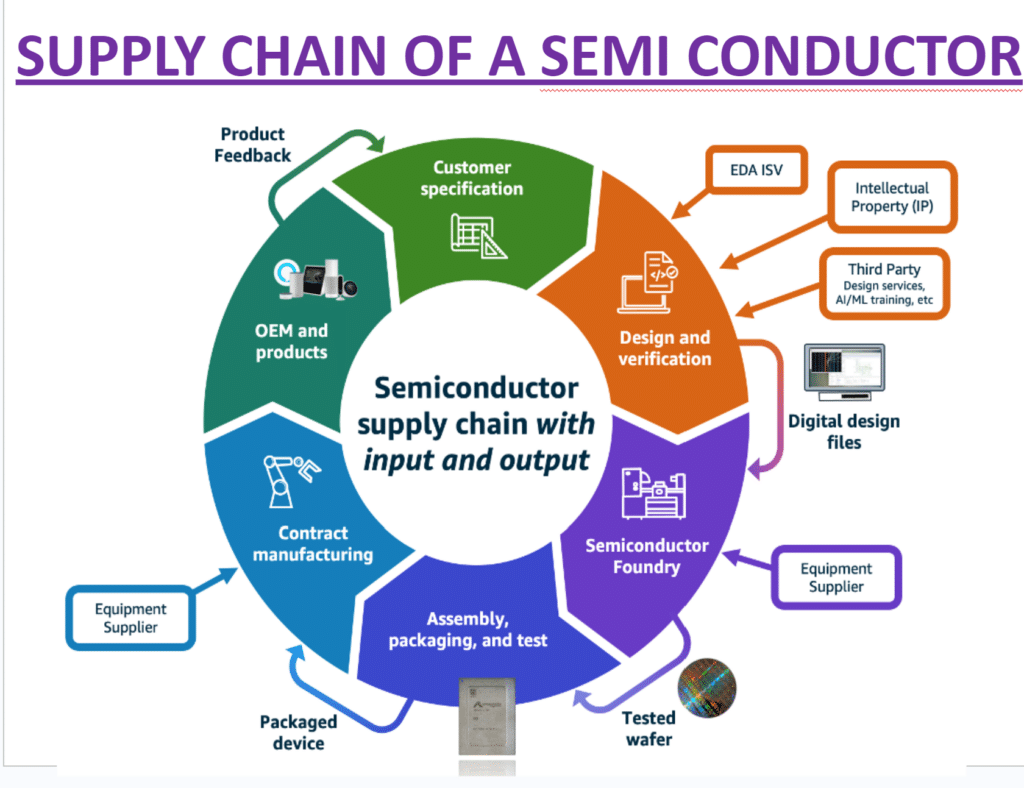

The semiconductor supply chain is a highly complex global network involving collaboration among integrated component service providers and system-on-board manufacturers to produce advanced systems such as the Akash missile. The process begins with extracting high-purity silicon from sand, a task made difficult by the limited availability of suitable raw material. Semiconductor manufacturing generally falls into two categories: fabrication facilities (fabs) and fabless companies focused solely on design.

This supply chain spans raw materials, design, manufacturing, logistics, and inventory management across multiple regions. For example, chip design may originate in the United States, fabrication may take place in Taiwan, manufacturing equipment may come from Japan, and system integration may occur in India. Such international coordination is essential to producing a single semiconductor component.

The semiconductor industry faces several threats, including disruptions caused by the COVID-19 pandemic, which resulted in severe global chip shortages. These shortages have affected not only consumer electronics but also the defence sector, intensifying competition for limited resources and extending production timelines.

One of the most serious challenges in defence electronics is the risk of counterfeit semiconductor chips. The United States encountered this issue during military operations in Afghanistan, where counterfeit components jeopardised mission-critical systems. As a result, the United States Missile Defense Agency formally acknowledged the threat and initiated a policy to replace all suspect chips to ensure authenticity.

Counterfeit semiconductor components pose risks across all industries. In missile systems, failures caused by counterfeit or defective electronics can result in catastrophic outcomes, including chip burnout, broken solder joints, corrosion, and complete mission failure. These risks emphasise the importance of securing a reliable and transparent semiconductor supply chain, particularly for applications requiring real-time control and guidance.

The evolution of warfare and missile technology reflects sustained technological progress and strategic adaptation. From basic weapons to sophisticated missile systems, each stage has reshaped military capabilities. The development of missile technology highlights the careful balance required between power, precision, and protection. As modern warfare grows increasingly complex, robust design, rigorous testing, and disciplined maintenance remain essential to ensuring the reliability and effectiveness of these critical defence systems.

| Challenges in semiconductor technology |

| In the rapidly evolving semiconductor technology landscape, multiple challenges threaten the integrity and functionality of critical components. From natural degradation to emerging security risks, maintaining reliability requires constant vigilance. • Decay of parts: Semiconductor components can degrade over time, affecting performance and reliability. • Rodent damage: Small animals can damage wiring and cables, potentially compromising entire systems. • Integrated threats: As technologies such as system-on-chip (SoC) designs become more integrated, vulnerability to internal and external threats increases. • Types of attacks: Semiconductor chips are susceptible to fault injection and side-channel attacks, which can expose sensitive data. • Security and trust: Ensuring the security and trustworthiness of semiconductor technology is essential, as reflected in initiatives such as the US CHIPS Act and India’s Semiconductor Conclave. • Growing demand: Rising global demand for semiconductor chips is driving new collaborations and elevating national security considerations. These challenges require coordinated action from industry, governments, and researchers to safeguard the technologies that underpin modern defence and civilian systems. |

| Missile Tech Challenges |

| Missile technology must operate under demanding real-world conditions that extend beyond theoretical design parameters. Extreme conditions: Missiles are exposed to direct sunlight, extreme temperatures, and variable weather conditions, often without the protection of controlled storage environments. Vibrations: Movement on tracked platforms or transport vehicles introduces vibrations that can affect system performance. Unpredictable terrain: Launches from uneven ground or undulating roads add further complexity to missile operation. Stabilisation systems: When missiles are launched from moving platforms such as ships or boats, stabilisation systems are essential to ensure accuracy and structural stability. These operational challenges underscore the level of engineering precision required to ensure missile systems remain reliable and effective in diverse and unpredictable environments. |

This article is based on a tech talk session titled ‘Security Loopholes from the Chip till the Missile’ at EFY EXPO 2023, Delhi, by Col Surender Kumar Rohilla, Colonel (SDA), Directorate of Standardization, Department of Defence Production, Ministry of Defence. Transcribed and curated by Nidhi Agarwal, Technology Journalist at EFY.