The concept of industry convergence has been an intrinsic element of the market fabric over time. Interactions and encounters between markets naturally lead to the exchange of ideas, processes, and technologies, Examples of this would be the collusion of agriculture and trade to create a banking and more recently, the overlapping of potential between healthcare and consumer electronics to create wearables. Further opportunities for fast, large scale convergence are only set to increase as our society continues to become more globally connected.

The concept of industry convergence has been an intrinsic element of the market fabric over time. Interactions and encounters between markets naturally lead to the exchange of ideas, processes, and technologies, Examples of this would be the collusion of agriculture and trade to create a banking and more recently, the overlapping of potential between healthcare and consumer electronics to create wearables. Further opportunities for fast, large scale convergence are only set to increase as our society continues to become more globally connected.

While the commentary on multi-industry convergence has gained greater visibility as a result of the digital revolution, test organizations are rarely examined for the same.

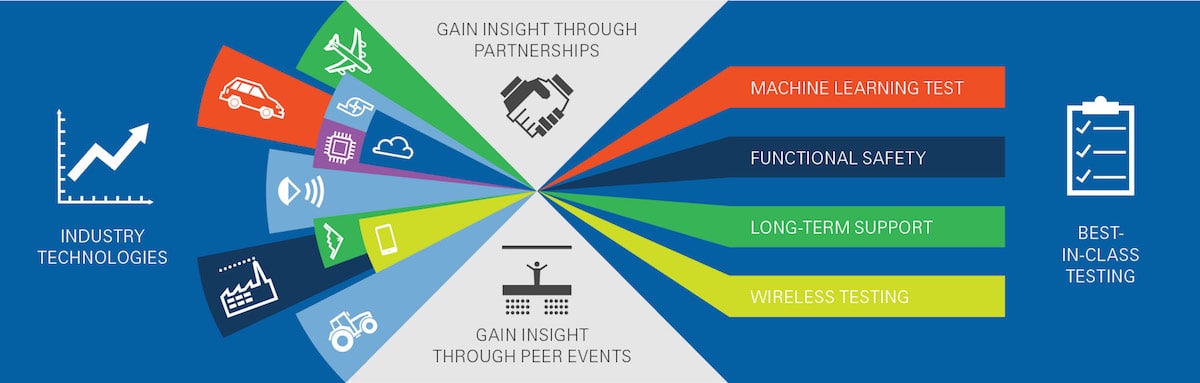

Convergence represents a dichotomy of threat and potential today and thus, best-in-class organizations are looking to tackle it directly by leveraging multi-industry test platforms and partnering with and learning from other organizations with multi-industry exposure.

Creating Test Innovation

According to a 2014 report by Gartner titled Industry Convergence: The Digital Industrial Revolution, industry convergence has been dubbed ‘the most fundamental growth opportunity for organizations’. For test organizations, this opportunity will come through learning and leveraging from other industries and pooling resources to accelerate innovation.

Convergence at its core revolves around the sharing of ideas that allow for learning from other industries to be leveraged in order to avoid wasting time and effort on creating solutions that already exist. While this is often discussed in the context of product innovation, the analogy can also be applied to test strategies. A clear example of this relates to functional safety in the heavy manufacturing industry, where a process named IEC 61508 was created to prove out the functional safety of embedded electronics. This was based on many years of learning and the safety-criticality of products and was later adopted by industries such as rail and automotive (EN 50126 and ISO 26262 respectively) where similar requirements were seen. Learning from experts in these standards can save time when adding functional safety testing to test strategy if and when it becomes necessary.

An added benefit that convergence provides is multi-industry resource pooling where vendors can now serve multiple industries simultaneously due to the alignment of their functional needs over time. In test, platform-based vendors can increase their industry-agnostic investment in things like processors or analog-to-digital converters to provide better quality products at lower prices to all industries. Such investments made in hardware, software, or services for test, multi-industry solutions, as opposed to single-industry options, maximize the opportunity for technology leverage.

Overcoming the Cost of Convergence

Despite its potential upside, convergence comes with its fair share on concerns as well, especially for test managers. Primarily, it adds complexity and demands the creation of more adaptable test platforms and even more flexible organizations.

The exchange of technologies between industries requires a concurrent update in testing and expertise in these newly created hybrid domains. Automotive hybrid powertrains, for example, now require systems that can test controls, mechanics, thermodynamics, electronics, software, and even battery chemistries. These requirements have led to the obsolescence of even the most recently made tests systems due to their inflexible, closed, and proprietary platforms. The changes that must be made today revolve around the use of more open and modular hardware and software that work across I/O types, programming languages, and vendors, along with well-defined APIs and interoperability standards.

This is exacerbated by the inability of organizations to visualize a way forward as the future in a converged world is much more hazy. Companies, test strategies, and test platforms must be designed keeping future trends and requirements in mind. For example, aerospace companies, which have historically moved very conservatively and relied on long product life cycles, now need to be nimbler as their supply chain grows more closely tied to that of consumer electronics. As a result, testers at aerospace test organizations need their testers must contend with a much faster technology refresh rate, and design test architectures that are adaptable to these changes. A potential solution for this would be to attend cross-industry networking events and to monitor other industries’ trade publications.

Collaborating with organizations that have multi-industry experience is another avenue that can be followed as they learn to absorb unforeseen circumstances more effectively and leverage best practices from other industries. Important problems can thus be outsourced to more cognizant third parties or strategic partnerships can be looked at in other industries around imminent trends like 5G and IoT. NVIDIA and Audi partnering to accelerate technology development or Boeing and Embraer collaborating to take market share from competitors are just two of the many examples of how this type of cooperation can lift organizations above their industry peers. Reevaluating where test happens in the supply chain and reviewing suppliers are also smart tactics. By being proactive, organizations can be prepared for what’s next and maybe even influence it.