Robots that plan in seconds, adapt on the fly and work in sync. This AI could change how factories run. Read more!

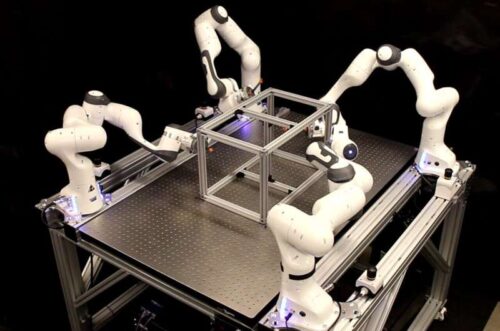

Scientists at UCL, Google DeepMind, and Intrinsic have developed an AI system called RoboBallet that enables groups of robotic arms to coordinate movements faster than real-time. The system could allow factories to adapt if a robot fails or if the layout changes, while also helping manufacturers optimize robot placement for efficiency and throughput.

RoboBallet is designed for assembly lines and factory floors, where multiple robots share spaces with obstacles. It automates the planning of robot movements, a task that is currently handled manually by specialists and can take hundreds of hours. With RoboBallet, movement plans are generated in seconds.

A key feature of the system is scalability. Traditional planning algorithms struggle when more than a few robots are involved because complexity grows. RoboBallet uses a graph neural network combined with reinforcement learning (RL). This allows the system to learn coordination strategies instead of memorizing layouts, making it suitable for large-scale industrial use.

In reinforcement learning, RoboBallet learns by trial and error, receiving rewards when tasks are completed, with higher rewards for faster completion. The graph neural network enables robots to treat obstacles and other robots as nodes in a network, helping them plan their movements.

According to a research paper published in Science Robotics, RoboBallet trained for a few days before it was able to produce plans in seconds. It managed up to 40 tasks with eight robotic arms in layouts it had not seen before.

The system has potential applications in car manufacturing, electronics assembly, and robotic construction, especially in settings where robots must work close together.

At present, RoboBallet focuses on reaching tasks, such as moving an arm to a point for welding. Future versions could extend to operations like pick-and-place, painting, and managing task order. Researchers also aim to adapt it for robot teams with different functions and more complex obstacles.

RoboBallet does not yet handle every factory case, such as tasks that must follow a set sequence or robots with different abilities. Its architecture is designed to support these features in future updates.