What if farm and forest waste could power ships and planes without changing their engines? A new process makes it possible and it’s closer than you think.

The shipping industry faces pressure to cut carbon emissions as regulations tighten and customers demand cleaner operations. Since the 1960s, heavy fuel oil, produced during the refining of gasoline, diesel, and kerosene, has powered most vessels, making the maritime sector responsible for about 3% of global greenhouse gas emissions. But changing this fuel source has been costly and complex.

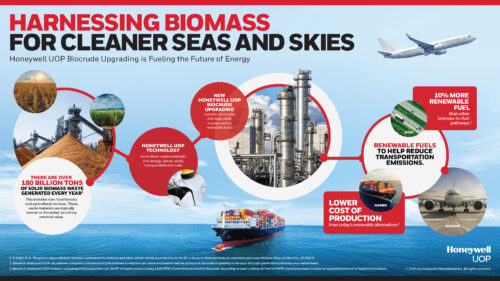

Honeywell’s new Biocrude Upgrading technology addresses this problem. It converts agricultural and forestry waste into renewable fuels that work like conventional ones. Using feedstocks such as crop residues and wood chips, the process produces lower-carbon marine fuel, gasoline, and sustainable aviation fuel (SAF). For ship operators, these ready-to-use or “drop in” fuels offer a way to cut emissions without changing existing engines or systems.

The fuels also have higher energy density than many current biofuel options, so ships can travel farther between refueling. This makes the technology useful for hard to abate sectors such as maritime transport, where range and efficiency matter.

Transportation cost is another issue the process helps reduce. Plant and agricultural waste can be converted into lower-carbon biocrude at feedstock collection sites, lowering the need to move raw materials. Honeywell’s process then refines this biocrude at large facilities into marine fuel, gasoline, or SAF, solving long standing challenges in turning biocrude into fuels with performance similar to conventional ones.

To make setup faster and simpler, the Biocrude Upgrading process can be deployed as a prefabricated modular plant. This design reduces on site work, shortens construction time, and lowers project risk for refiners and fuel producers.

This launch adds to Honeywell’s group of renewable and alternative fuel technologies developed over years. The company’s existing systems include Ecofining, Ethanol to Jet technology, Fischer Tropsch (FT) Unicracking technology, and UOP eFining, a process that converts green hydrogen and carbon into renewable fuels. These technologies give industries several ways to reduce carbon output while keeping performance and reliability.