Catch defects and foreign objects before they cause problems. The high-speed sensors can make inspections faster and give consistent results across industries.

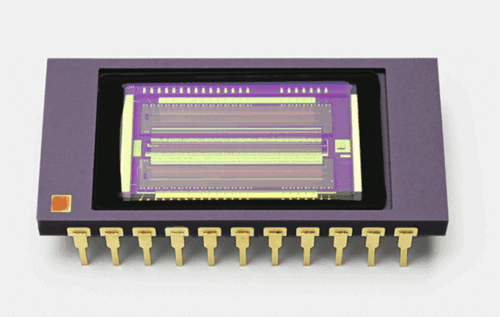

If you work in food processing, plastics, or electronics, you know how tricky it can be to catch defects or foreign objects quickly. Slow or unreliable inspection can waste materials, create safety risks, and cost a lot in recalls. Hamamatsu Photonics’ G17225 series InGaAs linear image sensors are designed to help you get fast, accurate, and reliable results right on the production line.

With a maximum line rate of 50 kilolines per second and data rates up to 20 MHz, these sensors let you inspect products in real time without slowing down operations. You can choose from four conversion efficiency options to match the sensor to your material or process. A built-in temperature sensor keeps performance stable even under changing conditions, and since the sensors operate at room temperature, there’s no need for complex cooling setups.

These sensors are particularly useful in food safety inspections, where quickly detecting foreign objects ensures your products meet quality standards. They’re also helpful for sorting agricultural products or inspecting electronics, where speed and accuracy matter. If you’re working with SD-OCT, the sensors provide the precision and high-speed data you need for detailed imaging.

Some of the key specifications of the G17225 series include:

- Image size: 12.8 × 0.025 mm, 12.8 × 0.0125 mm, or 12.8 × 0.25 mm

- Pixel configuration: 25 × 25 μm, 12.5 × 12.5 μm, or 12.5 × 250 μm

- Spectral response: 0.9–1.7 μm, with peak sensitivity tuned for different applications

For R&D teams, quality control staff, or industrial operators, the company claims that the series can help you work faster, get more accurate results, and feel confident in your inspections. These sensors are built to make your processes smoother and more reliable.