Many small factories in India are still unable to do remote monitoring. IoT and AI tools can help them track processes, work faster, and make better decisions. But how?

Even in a modern and fast-digitising India, we have seen that small and medium-sized enterprises (MSMEs) such as rice mills and stone crusher units struggle to access real-time operational insights due to a lack of affordable digital solutions. These businesses require remote visibility and actionable data to enhance productivity, manage resources efficiently, and identify process inefficiencies or bottlenecks, but conventional systems are often fragmented, costly, and difficult to configure or scale.

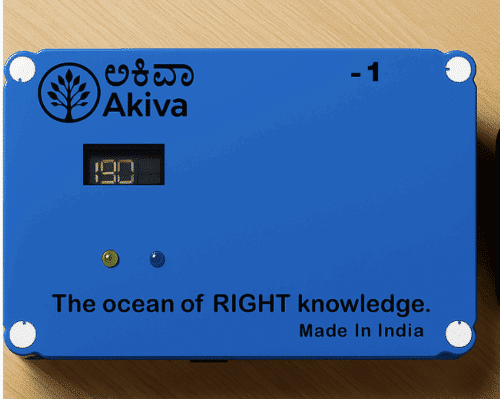

In a recent conversation, Ananth S Kulkarni, MD of Hexitronics, told Nidhi Agarwal from Electronics For You how they are helping MSMEs with universally configurable IoT devices and a cloud platform that automates dashboards and data analytics.

Do these MSMEs really need AI? This can be understood with an example. One can take a cement factory, for instance, where there is a long process from raw material input to bagging and dispatch. The factory has multiple departments, each managed by supervisors or operational managers who coordinate through daily meetings or urgent phone calls. Traditionally, the factory relies heavily on human intervention to meet production targets, which can be slow and fragmented.

When AI is integrated with sensors and gateways, the process undergoes significant changes. These sensors collect essential data such as conveyor speed, motor current, or temperature, which is fed to a dashboard for visualisation. However, operators and technicians often struggle to interpret these trends while managing their daily tasks effectively. AI solves this by processing real-time data from tables in the backend, applying formulas and computations that humans may not easily handle. It can then provide actionable suggestions, such as adjusting conveyor speed to improve production by a certain number of bags, something that cannot be achieved even with multiple supervisors. AI thus brings a higher level of productivity and decision-making into manufacturing. The trend now extends to AI assistants with voice capabilities, making it even more accessible.

“Some are hardware makers involved in hardware design and manufacturing. Others focus on cloud services, just like offering virtual machines for rent. Then some developers use these clouds to host datasets, analysts who work on data processing, and experts who handle AI integration. We provide all these professional skills together under one roof, solving the big problem. Currently, we are offering our gateways and IoT services at no cost. There are no subscriptions or charges for our customers,” Ananth added.

For the full interview, stay tuned.