Power failures can make suspended loads fall and cause accidents. Learn how smart holding-brake control keeps loads safe and saves energy.

Variable-speed drive (VSD) is a system that controls the speed and torque of an electric motor. Instead of running a motor at full speed all the time, a VSD adjusts the motor’s speed to match the needs of the machine or process. This improves energy efficiency, reduces wear on equipment, and allows precise control of motion. VSDs are widely used in applications such as elevators, robotics, and CNC machines. In these systems, especially on vertical axes, power failures pose serious safety risks. Suspended loads can endanger personnel and damage equipment if they fall or move unintentionally. You might need reliable ways to prevent accidental lowering or dropping of loads, and to maintain precise control over the motor shaft in all conditions.

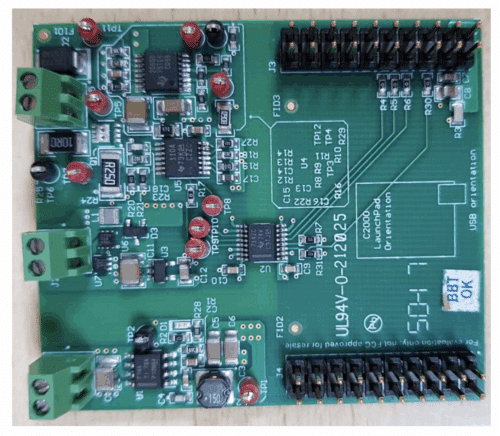

TIDA-01621, the reference design from Texas Instruments (TI) provides a solution by implementing smart holding-brake control for variable-speed drives. The holding brake latches when power to the braking coil is removed, de-energized, or cut off, and releases when voltage is applied to the coil. The operation is managed by enabling and disabling a smart electronic load switch and a solenoid-current controller, which supply regulated power to the brake coil. The design also includes robust protection at both the power supply input and brake coil output, improving overall system reliability.

The design uses a development kit to generate brake-control signals and perform diagnostics. It is suitable for servo drives, robotics, CNC systems, and can function as a dedicated holding-brake controller. The design supports brakes rated for 24 VDC and up to 2 A and incorporates a power-reduction feature when the brake is released to lower energy use and minimize brake-coil heating.

Safety and reliability are further enhanced through dual-switch control on both high and low sides. The high-side e-fuse protects against overloads and short circuits, while the low-side solenoid current controller regulates coil current. The digital isolator isolates brake-control signals from the controller, preventing faults from affecting the MCU. Using a smart load switch also reduces the number of discrete components, simplifying design and improving system robustness.

Brake coil connections are configured between the high-side switch and the low-side switch. The MCU generates digital signals that pass through the isolator to enable or disable the switches. This reference design demonstrates a complete solution for implementing a smart, current-regulated holding-brake controller in modern variable-speed drives. By providing a safe output signal to control an external brake, it helps prevent unintended load movement, improves functional safety, and simplifies integration for design engineers.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.