The affordable hardware surpasses current high-end models and has the potential to lead to a cost-effective, at-home health monitoring device in the future.

Credits:Image: Courtesy of the researchers

Mass spectrometry is a powerful technique for identifying chemical components in samples, which is useful for monitoring chronic illnesses such as hypothyroidism. However, its high cost, often in the hundreds of thousands of dollars, limits its use to laboratories, complicating the management of chronic diseases.

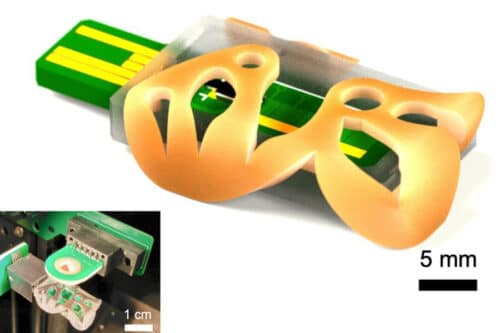

MIT researchers have made a breakthrough by 3D printing a low-cost ionizer, a crucial component of mass spectrometers, that outperforms existing versions. This compact device can be mass-produced and integrated into spectrometers using robotic assembly, making it more cost-effective than traditional ionizers. The 3D printing process allows for precise control over the device’s shape and the use of special materials to enhance its performance.

Low-cost hardware

The researchers utilized 3D printing and strategic optimizations to create a low-cost electrospray emitter for mass spectrometry that surpasses the performance of state-of-the-art ionizers. They crafted the emitter from metal using binder jetting, a process that builds an object layer by layer by spraying a polymer-based glue through tiny nozzles onto a bed of powdered material. The object is then heated to evaporate the glue and consolidate the powder. Following this, the emitters are electropolished to enhance sharpness and coated with zinc oxide nanowires, which provide the necessary porosity for effective liquid filtration and transport.

Thinking outside the box

The team tackled the issue of liquid evaporation in electrospray emitters, which can cause clogging, by turning it into an advantage. They designed their emitters as externally-fed solid cones with a specific angle that uses evaporation to control liquid flow, resulting in a spray with a higher ratio of charge-carrying molecules. They also redesigned the counter-electrode to prevent arcing, allowing for a safe increase in applied voltage, leading to more ionized molecules and improved performance. Additionally, they developed a low-cost printed circuit board with integrated digital microfluidics for efficient droplet transport.

The team plans to create a prototype combining their ionizer with a 3D-printed mass filter and is working on improving 3D-printed vacuum pumps, essential for a compact mass spectrometer.