By thinning silicon to the nanoscale, researchers enable conformal, high performance electronics for long term health monitoring and therapeutic applications.

Silicon has long been the backbone of modern electronics, but its rigid nature has limited its use in applications that require close and long term interaction with the human body. As demand grows for wearable, implantable, and bio integrated devices that can continuously monitor and interact with biological systems, conventional silicon electronics struggle to meet the mechanical and biological requirements of these applications.

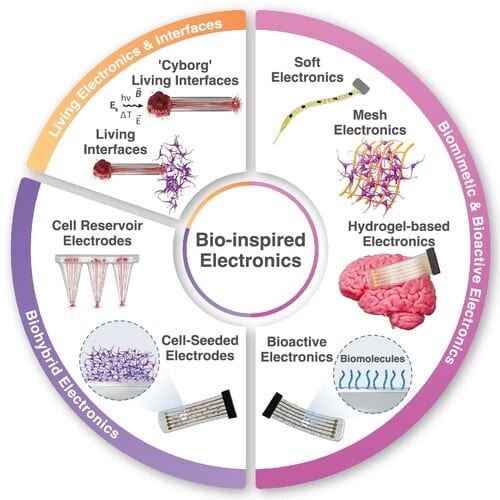

Researchers at Incheon National University are addressing this challenge by presenting a comprehensive roadmap for ultra thin crystalline silicon based bioelectronics. By reducing crystalline silicon to nanomembranes thinner than 100 nanometres, the material retains its high electrical performance and CMOS compatibility while becoming mechanically flexible and capable of conformal integration with soft biological tissues. The roadmap systematically connects silicon processing, transfer techniques, and biomedical applications into a unified framework.

The review outlines how traditional high temperature on wafer processes such as oxidation and doping can be combined with advanced transfer printing methods to produce flexible silicon nanomembranes. These ultra thin structures enable high performance electronic systems that can bend, stretch, and adapt to dynamic biological environments without sacrificing reliability. Because the technology remains compatible with established semiconductor manufacturing, it supports scalable production and integration of sensing, signal processing, and wireless communication within compact platforms.

In the near to mid term, ultra thin crystalline silicon enables flexible wearable and implantable devices for continuous physiological, thermal, and biochemical monitoring. Over the longer term, it supports closed loop bioelectronic systems including personalized neuromodulation, brain computer interfaces, bio integrated prosthetics, and bioresorbable implants.

Key features of the material include:

- Flexible silicon nanomembranes below 100 nanometres

- High electrical performance with CMOS compatibility

- Scalable manufacturing using established silicon processes

- Applications across wearables, implants, neuromodulation, and transient bioelectronics

Young Uk Cho, assistant Professor, Incheon National University says, “Our goal is to bring the performance and reliability of modern silicon electronics into long term, intimate contact with the human body and translate advanced electronics into real biomedical solutions.”