The ultrasound method helps find hidden battery problems in real time. It can reduce the risk of fires and failures during use and production.

To address the increasing risk of battery-related fires, researchers from Drexel University have developed a new ultrasonic testing method for battery safety and quality control. The system uses scanning acoustic microscopy to send low-energy sound waves through commercial pouch-cell batteries, capturing real-time internal data without damaging the cells.

Unlike traditional approaches—such as visual inspections, sample-based performance testing, or slow and expensive X-ray imaging—this method is faster, non-invasive, and suitable for integration into lab and production settings. The setup is low-cost and compact, designed to fit on a standard workbench, making it accessible for battery engineers, including those in the electric vehicle industry.

The system also includes open-source software that controls the hardware and performs rapid data analysis, reducing the need for specialized training or proprietary tools.

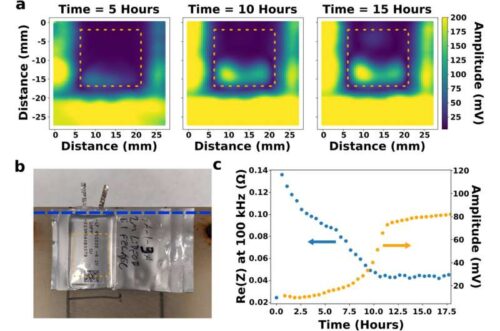

Ultrasound reveals how internal battery materials interact by tracking changes in the speed and behavior of the sound wave as it moves through the cell. This allows detection of hidden issues such as cracks, delamination, trapped gas, and material imbalance—flaws that are often invisible through conventional checks.

Since the testing can be done while the battery is operating, researchers can observe live electrochemical and mechanical behavior. This real-time insight is valuable for studying how new battery chemistries perform and fail during development.

Compared to X-rays, this approach is significantly faster and more affordable, making it feasible to test more batteries without slowing down production. The ease of use and automation further reduce human error and the time required to interpret results.

By catching hidden defects early, the Drexel-developed system reduces the chance of faulty batteries reaching the market—helping to prevent overheating, short circuits, and thermal runaway.

It enhances quality control in manufacturing and accelerates the development of next-generation batteries by offering continuous, detailed feedback. With broader adoption, this method can improve the safety and reliability of devices and electric vehicles used every day.

In the long run, it gives engineers and researchers a practical, scalable way to build safer battery systems—protecting users while supporting faster innovation.

Reference: Sam Amsterdam et al, Design of a low-cost ultrasonic testing instrument for battery metrology, Electrochimica Acta (2025). DOI: 10.1016/j.electacta.2025.146012