While the excitement around EVs hitting a projected 157 million by 2030 is palpable, a less visible but equally transformative story is unfolding behind the scenes.

Beyond the sleek designs and impressive specs, the industry leaders are laser-focused on something fundamental: ensuring every charge is not only fast but, above all, safe and remarkably efficient. This quiet dedication to innovation in electrical measurement is the bedrock of the EV revolution we’re all witnessing.

The need for electrical measurement in EV Charging

We need accurate electrical measurement in EV for a myriad reasons – the sensors help in:

- Efficient Power Transfer: Automated monitoring of current and voltage provides maximum energy transfer with the least losses.

- Stringent Safety Protocols: On-line monitoring of fault currents and leakage prevents electrical hazards.

- Intelligent System Control: Accurate measurement allows complex charging strategies, load balancing, and grid connection.

- Reliable Operations: Stable measurement systems ensure stable operation and extended life of EV charging infrastructure.

To support this across different requirements, two different architectures have come into place.

AC and DC Charging Architectures:

AC Charging: The Home and Workplace Standard:

This is the most common mode of EV charging at residences, workplaces, and most public locations, as it uses the onboard charger of the EV to convert AC power supplied by the grid into the DC needed for battery storage.

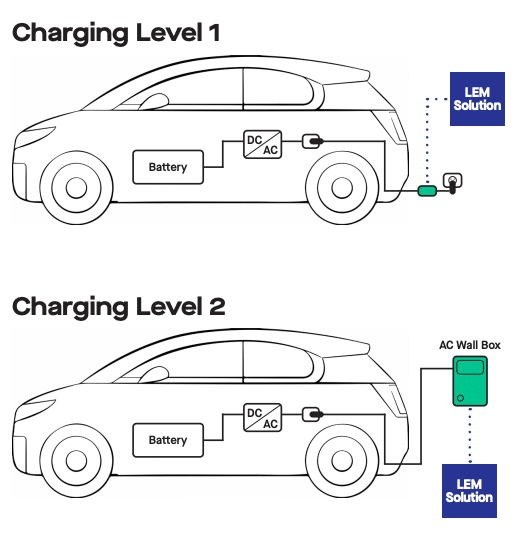

The power output of AC Charging is usually between 3.7 kW and 44 kW, determining the speed of charging. There are two types of AC Charging as shown in the image.

In Level 1 Charging, EV’s charging cable is plugged into a standard household electrical outlet. This gives a slowest charging rate, suitable for overnight charging or topping up during the day.

Level 2 Charging utilizes a higher-powered charging station, typically installed at homes, workplaces, and public charging stations. This provides faster charging rates compared to Level 1, making it more suitable for daily charging needs.

DC Charging: Highway High-Speed Refueling:

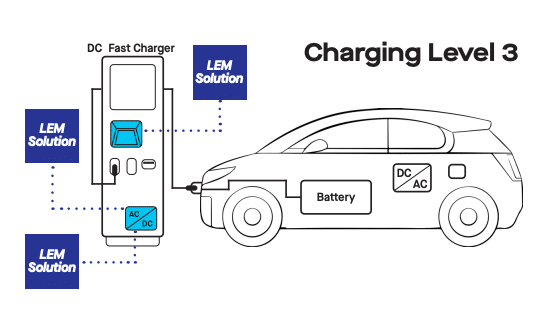

Direct current (DC), or Level 3, charging is mainly rolled out along highways and high-capacity routes for the purpose of high-speed refueling for EVs. These high-power charging points sidestep the onboard charger in a vehicle and supply DC power directly to the battery.

With output typically exceeding 50 kW and going up to 350 kW, DC charging allows drivers to accelerate quickly, which is most suitable for long-distance driving where quick battery recharge is critical.

LEM’s Current Sensors Across AC and DC Charging Architectures

LEM is a Switzerland-based leader in electrical measurement systems. Since 1972, LEM has been powering major technological revolutions with their end-to-end range of products.

Their sensors for AC and DC charging are widely recognized and implemented by charging network operators, manufacturers of charging stations, electric vehicle makers, energy companies, and commercial real estate developers.

Applications of LEM’s systems in AC Charging:

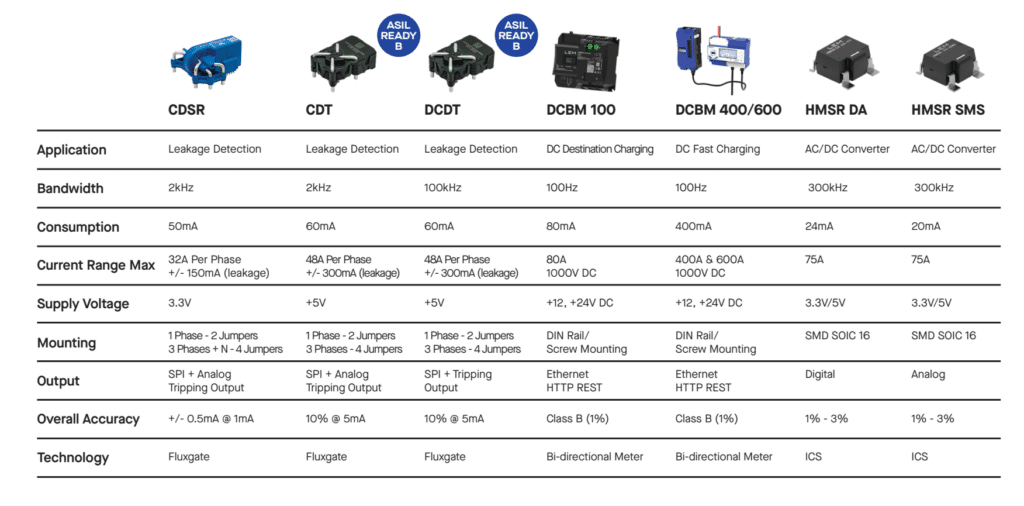

Leakage Current Detection (CDSR & DCDT)

In residential and office-based AC charging stations (Level 1 & 2), the CDSR and DCDT sensors are key elements used for detection of residual currents. These sensors are embedded in the charging circuitry to detect any leakage to earth, keeping the design compliant with safety regulations and safe from electrical danger for the users. Their high bandwidth and accuracy are vital for effective fault detection in different AC power delivery applications.

Integrated Current Sensing for Onboard Chargers (HMSR SMS & HMSR DA)

In the EV’s onboard AC/DC converter utilized in AC charging, the HMSR SMS and HMSR DA sensors offer accurate current feedback for effective power conversion and control. These ICS solutions provide reliable monitoring of the current being taken from the AC grid, maximizing the charging process and the lifespan of the vehicle’s battery.

Applications of LEM’s systems in DC Charging:

High-Power DC Metering (DCBM 400/600)

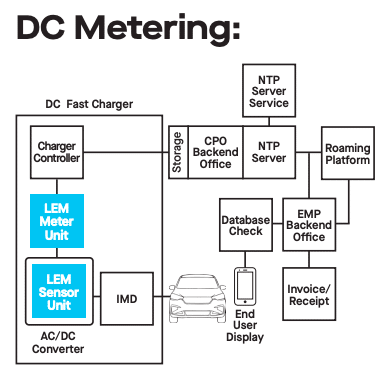

In highway high-power DC fast charging stations (Level 3), DCBM 400 and 600 series meters are critical for precise energy billing and complete system management. These sturdy DC metering devices accurately measure the high currents supplied directly to the EV battery.

For DC charging stations at destination locations such as workplaces or business districts, the bi-directional DCBM 100 meter supports accurate monitoring of energy to the vehicle. Its bi-directionality also makes it ideal for possible future use with V2G technologies at such locations.

Leakage Current Detection (CDT): This sensor extends critical leakage current detection to DC charging infrastructure, providing a critical layer of protection for high-voltage DC power delivery.

In India, Globetek is the sole distributor of these products – the company takes pride in having the longest standing alliance with LEM for trouble-free procurement, solutioning and services.