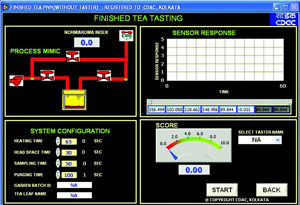

The e-nose-based aroma indices innovated through sustained experimentations in black tea fermentation process enable online smell monitoring and detection of optimal fermentation time for producing best flavour components in the manufactured black tea. The neural network-based self-learning computational models built into the e-nose software system permit fast declaration of quality scores of finished black tea, coherent with the organoleptic appraisals of the tea-tasters. The entire system is software-driven, field customisable and requires minimal operator intervention.

E-nose detects and discriminates among complex odours using a sensor array. The sensor array consists of non-specific sensors that are treated with a variety of chemical materials. The sensor array is exposed to the volatile molecules and smellprint (or fingerprint) is generated from it. Patterns from known odours are used to construct the database and train a pattern recognition system so that unknown odours can be classified and identified.

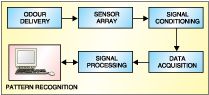

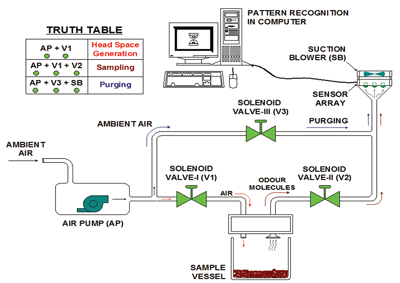

Fig. 2 shows the block diagram of e-nose system. The e-nose instrument comprises three elements—sample handling system, detection system and data processing system.

Sample handling is a critical step affecting the analysis by e-nose. To introduce the volatile compounds present in the head space (HS) of the sample into the detection system of e-nose, several sampling techniques are used:

1. Static head space (SHS) technique

2. Purge and trap technique

3. Solid-phase micro extraction technique

4. Stir bar sorptive extraction technique

5. Inside-needle dynamic extraction technique

6. Membrane introduction mass spectrometry technique Out of these, SHS technique has been observed to be useful for food and agro applications.

The most complicated part of electronic olfaction process is odour capture and the sensor technology deployed for it. Any sensor that responds reversibly to a chemical in gaseous or vapour phase has the potential to be developed in an e-nose format. Early e-nose used either polished wires in contact with porous rods saturated with different electrolytes, or thermistors coated with materials such as gelatin, fats or polymers. In the 1980s, advances were made with the appearance of chemically-sensitive sensors and developments in electronics and computing.

Some of the essential or desirable properties of the chemical micro-sensors to be used in e-nose are selectivity, sensitivity, speed of response, reproducibility, reversibility and portability.

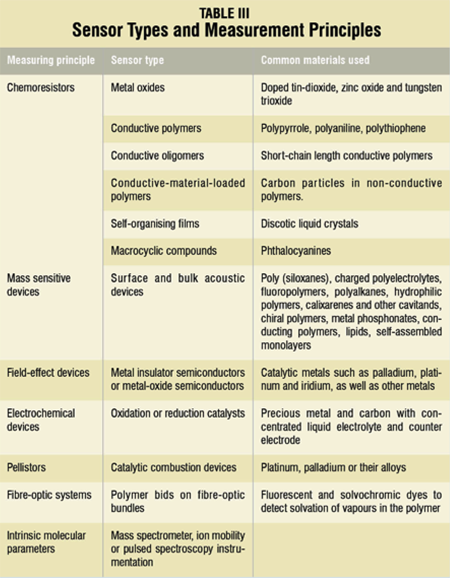

Table III shows sensor types and associated measuring principles used for e-nose. Out of these sensors, conducting polymer, metal-oxide semiconductor and bulk acoustic devices are most commonly used in commercial e-noses.

Advanced signal processing. In a machine olfaction system, two major building blocks are the sensors and the pattern classification engine. Interfacing electronics, signal conditioning and data acquisition circuits provide the crucial link between these two blocks.

Olfaction sensors have a wide range of transduction mechanisms. But at the output of these sensors, an electrical signal (say, voltage or current) proportional to the gas/liquid exposure on the sensor surface is required. Interface circuits convert the sensor output parameters into an electrical signal for further processing.

In chemo resistor sensors a change in resistance is obtained on exposure to the odour particles. A voltage divider or a Wheatstone bridge circuit can be used as the basic interface circuit. Interfacing circuits of quartz crystal microbalance or surface acoustic wave devices are required to measure shift in the resonance frequency.

The interfacing circuits are followed by the signal-conditioning block, which is basically analogue conditioning of the electrical signal through five sequential stages—buffering, amplification, filtering, conversion and compensation.

Data acquisition involves gathering signals from measurement sources, i.e., sensors, and digitising the signal for storage, analysis and presentation on a personal computer (PC). Data acquisition systems are available in many different PC technologies for flexibility and application-specific customisation. Various options include peripheral component interconnect (PCI), PCI eXtensions for instrumentation (PXI), PCI Express, PXI Express, Personal Computer Memory Card International Association (PCMCIA), USB, IEEE 1394, parallel or serial ports for data acquisition in test, measurement and automation applications.

Signal pre-processing. Signal pre-processing means extraction of relevant information from the responses obtained and preparation of this information for multivariate pattern analysis. The major aspects of pre-processing are baseline identification and manipulation/determination, compression and normalisation or final preprocessing.

Baseline is the sensor response to a reference analyte and proper accommodation of the same into the actual sensor response is expected to provide compensation due to drift, scaling and enhancement of contrast and better identification. Three different techniques of baseline manipulation are differential, relative and fractional.