Laser distance meter

Laser distance meter can be a very useful tool for measuring distances with good precision without physical contact. In fact it allows for the most sensitive and precise length measurements, faster recordings encompassing large ranges. All these qualities do not come with a single technique so different techniques are used based on specific requirements. Some of the most important techniques used for laser distance meters are as follows:

1. Triangulation is a geometric method, useful for distances in the range of a millimetre to many kilometres.

2. Time-of-flight measurements (or pulse measurements) are based on measuring the time-of-flight of a laser pulse from the measurement device to some target and back again. Such methods are typically used for large distances.

3. The phase-shift method uses an intensity-modulated laser beam. Compared with other techniques, its accuracy is lower, but it allows unambiguous measurements over larger distances and is more suitable for targets with diffuse reflection.

4. Frequency modulation methods involve frequency-modulated laser beams, for example, with a repetitive linear frequency ramp. The distance to be measured can be translated into a frequency offset, which may be measured via a beat note of the sent-out and received beam.

Fig. 4 shows a distance meter.

Vibration tester

Machines are used in nearly every aspect of our daily life; from the vacuum cleaner and washing machine we use at home, to the industrial machinery used to manufacture nearly every product we use on a daily basis. When a machine fails or breaks down, the consequences can range from financial loss, personal injury and possible loss of life. For this reason, early detection, identification and correction of problems is paramount to anyone involved in the maintenance of industrial machinery to ensure continued, safe and productive operation.

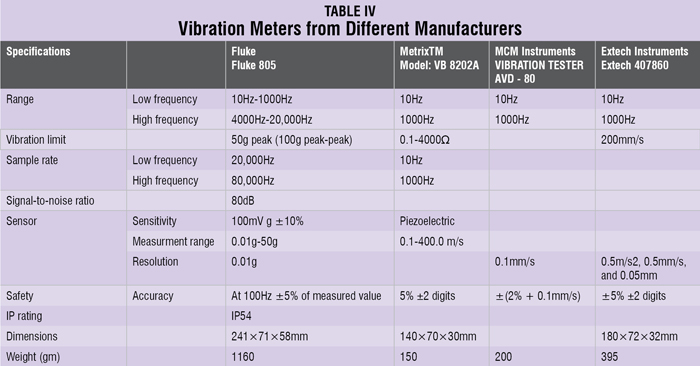

Vibration levels give a very good idea of the state of a machine. It is evident from the fact that we naturally touch a rotating machine and feel the vibrations to see if it is running right. Even machines in the best of operating condition will have some vibration because of small, minor defects. Therefore each machine will have a level of vibration that may be regarded as normal or inherent. However, when vibration increases or becomes excessive, some mechanical trouble is usually the reason. Various instruments have been developed to actually measure a machine’s vibration level and assign it a numerical value. Fig. 5 shows a vibration meter and Table IV shows features of some vibration meters from different manufacturers.

These are all the basic equipment that a field engineer would need depending on the project at hand. You can also add a multimeter to the list, which is also a useful tool in many cases. Refer buyers’ guide on handheld digital multimeters published in February 2013 issue for details.

The author is a technical editor at EFY