The research highlights how re-engineered soft magnetic materials reduce losses at tens of kilohertz, aiding EVs and high-frequency power applications.

As demand for energy-efficient power electronics grows, the performance of soft magnetic materials has become a key factor in reducing losses in transformers, inductors, and other components. With the rise of AI-focused data centres, electric vehicles, and high-frequency power conversion, conventional soft magnetic materials struggle to maintain efficiency, as energy losses increase at higher operating frequencies.

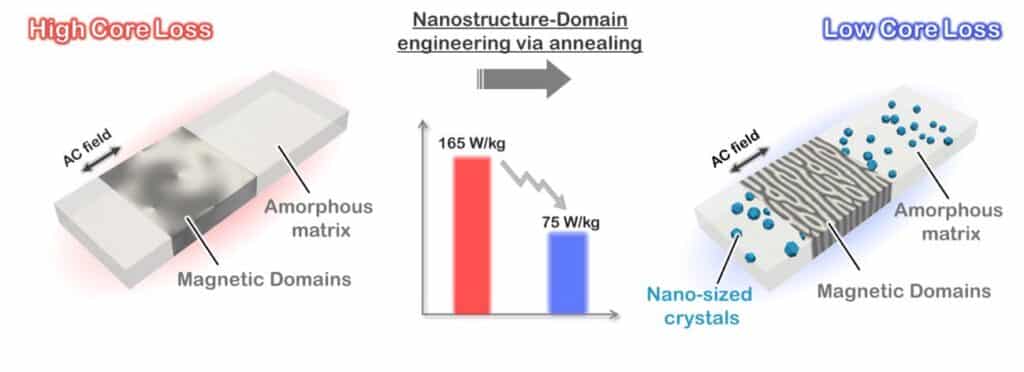

To address this, researchers from the National Institute for Materials Science (NIMS), Tohoku University, and the National Institute of Advanced Industrial Science and Technology (AIST) have developed a technique to improve iron-based soft amorphous ribbons. By controlling the nanostructures and magnetic domain structures, the team achieved more than a 50% reduction in core loss compared to the initial amorphous material. The material shows high performance at frequencies of several tens of kilohertz, relevant for next-generation transformers and EV drive power supply circuits.

The method integrates optimized thermal treatment to engineer the material at the nanoscale, resulting in precise domain structures that reduce energy loss. The material’s efficiency improvements support the development of high-performance transformers, more efficient electric machines, and progress toward carbon neutrality.

Key features of the research include:

- Controlled nanostructure and magnetic domains in iron-based soft amorphous ribbons

- Over 50% reduction in core loss

- Optimized thermal treatment for precise structural control

- High performance in tens of kilohertz frequency range

- Applications in high-frequency transformers and EV power supply circuits

Looking ahead, the research team plans to fabricate prototype transformers and test integration of the material into real power conversion circuits as this approach opens the door to high-frequency, low-loss power electronics that can meet future energy efficiency demands