Facing range and motor control issues in light EVs? This inverter design claims to cut redesign work and speed up development. Read on to know more!

Light electric vehicle makers face three core challenges: improving motor efficiency, extending driving range, and reducing development time. Designing a traction inverter that meets safety standards, handles different battery voltages, and scales across vehicle types often requires major redesign, repeated validation, and higher cost.

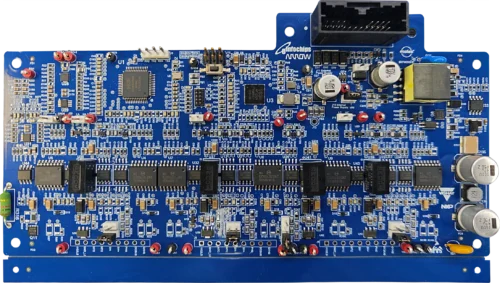

To address this, eInfochips, in collaboration with Vishay Intertechnology, has introduced a low-voltage traction inverter reference design for LEVs. The platform targets 36V to 96V battery systems and supports power levels from 3kW to 15kW. It allows design engineers to reuse the same core architecture across e-bikes, e-scooters, e-three-wheelers, compact utility EVs, and off-road electric machines without starting from scratch.

At the system level, the reference design reduces integration complexity. It combines hardware and embedded software into a single platform built on the NXP microcontroller series and a half-bridge MOSFET power module from Vishay. Functional safety support up to ASIL B and pre-compliance with IEC 61508 help engineers address safety requirements early in development. Production-grade software modules further reduce validation effort.

The modular structure directly tackles scalability issues. Instead of redesigning the inverter for each vehicle category, engineers can adapt the same control and power architecture to different voltage and power requirements. This shortens prototyping cycles and lowers design risk when expanding product portfolios.

The inverter is divided into two main blocks: a control board and a power board. The control board, based on the MCU platform, manages motor control and communication. It supports SPI and CAN interfaces. ADCs measure voltage and current feedback from the power stage to estimate motor position and generate PWM signals for induction motor control. This setup helps engineers implement efficient motor control algorithms while maintaining real-time diagnostics.

The power board uses transfer-molded MOSFET half-bridge modules from Vishay. It converts DC from the battery into three-phase AC to drive the motor. The design focuses on compact layout and improved thermal handling. Optimized PWM control reduces switching losses, improving overall inverter efficiency and supporting longer vehicle range.

Thermal management and safety mechanisms are integrated within a single compact form factor. This reduces board-level complexity and helps manage EMI and heat dissipation, which are common pain points in dense LEV designs.

The reference design also includes application software with a PC-based GUI. Through the CAN interface, engineers can monitor parameters in real time, configure settings, and run diagnostics. The software handles signal acquisition, motor control algorithms, CAN communication, fault handling, and gate driving. This reduces the effort required to build custom test and validation tools during development.

For cost-sensitive LEV markets, the platform improves bill-of-material optimization through design reuse. Manufacturers can use the same inverter base across electric two-wheelers, three-wheelers, shared fleets, compact tractors, mini excavators, utility task vehicles, and performance e-scooters. The scalable architecture minimizes major hardware changes while supporting different power ratings. To read more about this reference design, click here.