In simple terms, sensor interfacing is the process of connecting sensors to microcontrollers or other processing systems. This allows microcontrollers to acquire, process, and respond to sensor data, facilitating real-time environmental interaction.

This interface enables microcontrollers to:

- Acquire the signals from sensors

- Process and interpret the data from the sensor

- Control devices or actuators based on the input provided by the sensors

Table of Contents

Importance of Sensor Interfacing

Sensor interfacing plays a crucial role in modern technology, enabling:

- Smart devices interacting with the environment

- In robotics to enable real-time sensory feedback for navigation and control

- Smart homes

- Medical Devices

- Industrial automation

Brief overview of Sensors and Basic principles of sensor interfacing

Sensor: To convert physical quantities into measurable electrical signals, we use sensors. A sensor mainly consists of a sensing element, a transducer, signal conditioning circuits, and an output interface

Check out the article Sensors and Sensing Solutions for a detailed idea of sensors and the different sensing solutions.

Sensor Interfacing Principle

Sensor interfacing integrates hardware and software components to achieve accurate and reliable measurement and control. By understanding the characteristics of the sensor, applying appropriate signal conditioning, converting signals, processing data, and ensuring effective communication, a robust sensor interfacing system can be developed for various applications.

The explanation of each topic given above is explained in a detailed manner in this article.

Types of Sensors

Before we go forward with the detailed process of interfacing a sensor, let us first try to understand the various categories of sensors.

Sensors can be classified into different types. Below are some common classifications of sensors

Based on the output type

Analog Sensors: These types of sensors produce a continuous output signal that is proportional to the measured quantity.

Digital Sensors: These types of sensors produce data in digital format through communication protocols.

Based on the type of measurement

Temperature Sensor: Used to measure temperature variations

Curious about temperature sensor applications? Dive into our PIC16F877A-Based Temperature Monitoring System project.

Pressure Sensor: Used to measure the pressure of gases or liquids.

Check out the project Home-Made Pressure Sensor to learn how to make your own DIY pressure sensor

Light Sensor: Used to detect light intensity

To learn more about light sensors and the concept of LDR, check out our detailed article What Is Light Dependent Resistor (LDR)?

Motion Sensor: Used to detect the movement or displacement of an object.

The practical application of motion sensors can be visualized through this interesting project Wristband Based GPS Navigation System

Humidity Sensor: Used to measure the moisture content in the environment

Check out the Humidity Indicator and Controller project, a simple and effective solution to monitor the humidity level.

Gas Sensor: Used to find out the amount of gas in the environment.

Here is a guide to Designing Wireless Gas Detection and Monitoring Systems

Based on the working principle

Resistive Sensors: Change resistance based on the physical quantity measured

Capacitive Sensors: These sensors change the capacitance based on the position of the object or the proximity.

Inductive Sensors: These sensors use electromagnetic induction to detect metallic objects or measure displacement.

Piezoelectric Sensors: These sensors work by the principle of generating a voltage when subjected to mechanical stress

Based on the power supply

Active Sensors: These sensors require an external power source to operate

Passive Sensors: These sensors do not require an external power source to operate

To understand the passive sensors better check out the Infrared Sensor-Based Power Saver project

Based on the contact type

Contact Sensors: These sensors require physical contact with the object being measured

Non-Contact Sensors: These types of sensors can measure physical quantities without needing physical contact.

Based on the application

Industrial Sensors: Used for industrial manufacturing and automation.

Check out the article Sensors for Industrial Automation to get a clear understanding of industrial sensors

Automotive Sensor: Used in vehicles for engine performance monitoring

Environment Sensor: Used for monitoring environment air quality, humidity, etc.

The project Environment and Weather Monitoring System is an interesting project that you can carry out. Also, check out our Air Quality Monitoring Device project.

Choosing the Right Sensor for Your Application

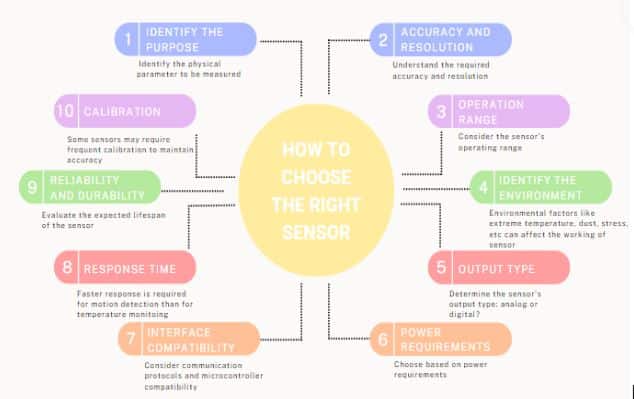

Here is a ten-step guide to help you pick the perfect sensor for your project.

Now that we have understood the different categories of sensors available in the market and how to pick the right one for your application, let us delve into the technical aspects of sensor interfacing.

Signal Conditioning for Sensors

What is signal conditioning?

Modifying, filtering, or amplifying the output signal from a sensor is called signal conditioning. This modification is done using a microcontroller or any other electronic system components.

Signal conditioning is performed to manipulate the sensor’s raw data to satisfy the electrical and processing requirements.

Why signal conditioning is important?

Many sensors, especially analog sensors, do not provide output signals that can be directly used for further processing. For example, an accelerometer can provide an output signal that may be too weak; this signal might not fall within the input range of the control system.

Another important factor is the noise susceptibility. Weak signals are prone to noise and interference, and they can compromise the accuracy of data.

To overcome these challenges, we need to amplify the signal to a level suitable for the control system and filter the output signals to remove noise. This is where signal conditioning techniques play a vital role, enabling precise and accurate measurement.

To conclude, signal conditioning helps to:

- Improve SNR ratio (Signal to Noise)

- Match sensor output to system requirements

- Reduce noise and other interferences

- Enhance signal fidelity

Types of Signal Conditioning

Let’s look into different types of signal conditioning techniques:

Amplification

The process of boosting a weak signal to increase resolution and accuracy is called amplification. The most commonly used amplifier is operational amplifier (Op-amp). Op-amp is a high-gain voltage amplifier that amplifies the low-level voltage signals.

They provide high input impedance and low output impedance. In case you are wondering what impedance is, it is simply how much a circuit resists the flow of electricity.

The higher the impedance, the greater the opposition to current flow. In an Op-Amp, high input impedance prevents signal loss and loading, preserving the original signal with minimal distortion and enhancing fidelity. Conversely, the low output impedance allows efficient signal transfer and better load regulation, maintaining signal integrity.

So, to sum up, an Op-Amp ensures a strong, unaffected output without loading the input signal, leading to accurate voltage measurements, reliable signal transmission, efficient power transfer, and reduced errors in measurement and control systems. To understand the Op-amp in a detailed manner, check out this video tutorial.

Filtering

The process of removing noise, interference, and unwanted frequencies is known as filtering. A filter allows specific frequency components of a signal to pass through while rejecting others.

So, when the signal from a sensor is applied to the filter, the filter selects the specific frequencies based on its design (High-pass Filters, Band-pass Filters, Band-stop Filters). After selection, the undesired frequencies are attenuated and then the filtered signal is fed as the output for the next stage of processing.

The different types of filters and their theoretical concepts are explained here Filters Using Op-Amps.

Excitation

In simple words, excitation is a technique that provides a controlled energy source to a sensor, enabling it to generate a measurable output signal. The type of excitation whether current or voltage to be used depends on the requirement of the sensor.

Isolation

Isolation is a signal conditioning technique that separates the input and output signals of a sensor, protecting systems from high voltages, currents, or electromagnetic interference. This can be achieved through the use of optical, capacitive, or transformer-based isolation.

Linearization

Sensors often exhibit non-linear behavior due to physical limitations, which can result in inaccurate measurements. Linearization is the process of correcting this non-linearity to produce a linear output signal. It begins by identifying the sensor’s response and pinpointing the non-linear regions of the response curve.

Mathematical corrections are then applied to adjust the signal, making the output linear. This ensures more accurate measurements by aligning the sensor’s response with the desired linear relationship.

Common Examples

Figure 4: Some common circuits and their signal conditioning requirements

Watch the Signal Conditioning in Instrumentation video for more information.

Analog-to-digital Conversion (ADC)

After the signal output from the sensor is conditioned, it needs to be converted into a digital format, especially in the case of analog sensors. For this, we use an ADC. But have you ever wondered why we can’t use analog data directly for digital systems?

Most modern systems, like microcontrollers and computers, are designed to process data in digital format because analog signals are continuous and can have infinite possible values within a range (e.g., 0-10V). Processing these infinite values can overwhelm digital systems and lead to signal degradation or information loss.

Additionally, analog signals lack clear boundaries between signal and noise, making it harder to define precise thresholds. Converting analog signals to digital ensures accurate representation, efficient processing, reliable storage, and noise-resistant communication.

Now that we have understood the fundamental reason behind the conversion, let us look at how the process takes place.

Firstly the ADC captures the analog signal at regular intervals and then these sampled values are converted to discrete digital levels, based on the resolution of the ADC (Number of digital bits that represent the continuous signal). After conversion, the data is represented in digital levels as binary codes (0s and 1s).

The various techniques of Analog to Digital Conversion are explained in a detailed way, check it out to learn more.

Criteria for Choosing Communication Protocols in Digital Sensor Interfacing

We know communication protocols are standardized rules and procedures that enable digital devices to exchange data efficiently. Without these protocols, the data transmission would be chaotic and there would be data errors and loss more frequent.

Following the communication standards allows the transmission of data in a standardized format, allowing seamless data exchange between devices and efficient bandwidth use.

For example, in the case of a temperature sensor, the I2C protocol is an ideal choice due to its low-speed requirements and low power consumption. Temperature sensors typically transmit small amounts of data at slow intervals, and I2C provides sufficient bandwidth to handle this, making it energy efficient.

On the other hand, using the SPI protocol for a temperature sensor may result in unnecessary higher power consumption since SPI operates at higher speeds, which are not required for slow-changing data like temperature.

However, when dealing with sensors like accelerometers and gyroscopes, which require high-speed data transfer (up to several Mbps) for accurate motion sensing, SPI becomes the preferred protocol.

SPI’s full-duplex communication enables simultaneous data transmission and reception, which is crucial for real-time monitoring and precise control in motion-sensitive applications.

For applications that require medium to high data rates, but where full-duplex communication or ultra-high-speed is not essential, UART can be a valuable option. UART is often used in point-to-point communications where moderate data rates suffice, making it suitable for systems that don’t demand the high speeds of SPI but still need reliable and continuous data transmission.

So, before designing your next-gen device, let us quickly grasp the concept and fundamental differences between the Serial, Parallel, and Wireless protocols. Let us delve into a comprehensive comparison of these three categories, examining their advantages, disadvantages, and applications to inform your design choices.

The various communication protocols and their characteristics are mentioned below:

| Protocol | Advantages | Disadvantage | Types | Example |

| Parallel | → Simultaneous Data Transmission → High-Speed Data Transfer → Efficient for short distance | → Half-Duplex → Complex Wiring → Limited Signal Integrity Over Distance → Clock Skew Issues | → PCI → ATA → ISA | → Printers → FPGA-based data acquisition → Internal buses in computers |

| Serial | → Simpler wiring required → Efficient for long-distance data transfer → Cost-effective option → Reduced interference | → Slow data transfer → High latency → Requires synchronization to avoid errors | → I2C → SPI → USB | → Sensor measurements → Microcontroller communication → Peripheral devices |

| Wireless | → Eliminates the need for physical connection → Low maintenance required → Easily expandable | → Comparatively lesser transmission speed → Prone to interference and security issues → Power consumption and cost concerns | → Wi-Fi → IOT devices (Zigbee, LoRa) → Smartphones (Bluetooth) | → Home & Networking → Smart automation → Remote sensing applications |

Interfacing Sensors with Microcontrollers

Let us understand how to interface a sensor with the microcontroller with this example where we try to interface the LM35 temperature sensor with Arduino Uno.

Analog Sensor

- Selecting the sensor and microcontroller

After following the 10-step process discussed in the previous section, the sensor chosen here is the LM35 sensor which has a linear output, where 10 mV corresponds to 1°C. It is widely used due to its simplicity and ease of integration with microcontrollers like Arduino UNO.

| Parameters | Value |

| Accuracy | ±0.5°C at 25°C |

| Interface type | Analog output |

| Operating temperature range (°C) | -55 to 150 |

| Supply voltage (min) (V) | 4 |

| Supply voltage (max) (V) | 30 |

| Output Voltage | 10 mV/°C |

- Understanding the pin-out diagram of LM35

- Vs: Power Supply (4V-30V)

- Vout: Analog Voltage Output (10 mV/°C)

- GND: Ground

- Understanding the pin-out diagram of Arduino Uno

- Analog pins (A0-A5): These are used for reading analog signals

- GND: Ground

- 5V: Supplies power to the sensor

- VIN: To power the Arduino with an external voltage source

Hardware Connection

Using a jumper wire, connect the pins accordingly:

| LM35 | ARDUINO UNO |

| VS | 5V pin |

| GND | GND |

| Vout | A3 |

To learn more about the hardware connections, watch this detailed video.

ADC

We know that the LM35 outputs an analog voltage corresponding to the temperature. Since the Arduino can only process digital data, the built-in Analog-to-Digital Converter (ADC) converts the analog voltage from the sensor into a digital value. This is done by using the following formula:

| ADC Value = (Sample Voltage*1024)/ Reference Voltage |

Now, from this, the temperature can be calculated as,

| VOUT = T(°C) × 10mV/°C |

Writing Code

The working of the code must be in the following way:

- Initialize serial communication

- Reading ADC Value

- ADC to Voltage Conversion

- Temperature Calculation from voltage

- Output display for real-time monitoring

Here is a sample code snippet.

If you are interested in working on a DIY digital thermometer project, check out this amazing project Arduino-based Digital Thermometer.

Practical Considerations

- Ensure that the Arduino’s 5V power supply is stable, as fluctuations can affect the accuracy of the temperature readings.

- The LM35 should be placed in a location that is free from direct sunlight or other heat sources to get an accurate reading.

- If the sensor readings fluctuate, consider adding a capacitor between the VCC and GND pins of the LM35 to reduce noise.

Digital Sensor

Now that we have discussed the analog sensors, let us try to understand for digital sensor how the interface is different.

For a digital sensor like the DHT11, the primary difference from an analog sensor lies in the data output format. While analog sensors output a continuous voltage signal that needs to be converted via an ADC, digital sensors like the DHT11 provide data in a ready-to-use digital format.

To transmit this data, the DHT11 uses a 1-wire serial communication protocol (sending data over a single pin). As the data is already digital, there is no need for an ADC, simplifying the interface process.

The sensor pins include the Vcc, data pin, and GND. The data pin is directly connected to the digital pin 2 of the microcontroller as shown below in the connection diagram

Writing of code includes an extra step of including the DHT11 library only! Check out this detailed video for more.

Having explored the analog and digital sensor interface, we will proceed to the data processing stage. Next, we will focus on filtering out noise and interference, ensuring the accuracy and reliability of sensor readings.

Handling Noise and Signal Interference

Noise in sensor systems can be of various forms, including white noise, low-frequency noise, electromagnetic interference, and high-frequency noise. To mitigate these, both hardware and software solutions are employed, such as:

Hardware Solutions

- Grounding Techniques: Implementing single-point or star grounding prevents ground loops, reducing noise.

- Cable Management: Proper routing and shielding of cables minimize noise.

- Shielding: Enclosing sensors in metal housings or using shielded cables can block external electromagnetic interference.

Software Solutions

- Digital Filters: Applying low-pass, high-pass, or band-pass filters in software helps remove unwanted noise from the acquired sensor data.

- Averaging Techniques: Computing the average of multiple sensor readings can smooth out random fluctuations.

- Advanced Filtering Algorithms: Utilizing methods like Kalman filters can enhance signal estimation in the presence of noise in the sensor data.

By integrating these strategies, the integrity and accuracy of sensor data can be significantly improved.

An overview of the most commonly used filters are listed below:

Low-Pass filter

- Definition: The circuit that only allows the frequencies below a certain cutoff frequency to pass through and blocks the frequencies above the cutoff is known as a Low Pass Filter.

- When to use: If your sensor measurements are prone to sudden spikes in noise, use a low-pass filter.

- Example: If your temperature sensor readings are showing sudden fluctuations due to noise or when you need to filter out the high frequency from the analog sensor.

High-Pass filter

- Definition: The circuit that only allows the frequencies above a certain cutoff frequency to pass through and blocks the frequencies below the cutoff is known as a High-Pass Filter.

- When to use: When you want to remove the drift noises or baseline fluctuations in sensor data, it is ideal to use this filter.

- Example: While using an accelerometer, we need to measure only the rapid changes in the movements. To avoid gravity’s constant acceleration we use this filter.

Moving average filter

- Definition: The principle behind the moving average filter is quite simple. This digital filter reduces noise by averaging a set of recent data points.

- When to use: Useful when your sensor output varies frequently but you don’t want these drastic changes in the output.

- Example: Used in sensors like humidity sensors to avoid the rapid jumps caused by environmental changes.

Kalman filter

- Definition: To measure the true value of the variable from the sensor measurements when there are noises and other interferences present and when the system changes over time, we use the Kalman filter.

- When to use: If you want to predict and correct the sensor readings over time. Kalman filters are best used when the state of a system changes over time and when the sensor data contains certain uncertainties and noises.

- Example: The most popular use of the Kalman filter is in GPS and accelerometers where we need to estimate and correct the position and velocity of a system in real-time.

There are several other filters that we can use for noise handling such as Band-Pass filters, Band-Stop filters, etc.

Data Acquisition System for Sensors

The final step in sensor interfacing involves data acquisition, leveraging ADCs, microcontrollers, and software to extract valuable insights from sensor outputs. Data Acquisition (DAQ) is the process of collecting, measuring, and recording signals from sensors or other physical inputs.

After sensors convert physical measurements into electrical signals, the DAQ system processes this data for storage and further analysis. DAQ systems consist of hardware components which we have already talked about, the ADCs, amplifiers, and communication interfaces that connect to a microcontroller or a computer, enabling real-time data processing and logging.

Once the data is processed (either in analog or digital form), it is transmitted via a communication protocol to the data storage system. This data can be stored locally on an SD card, hard drive, or cloud storage, depending on the system requirements. The stored data can then be retrieved for further analysis, monitoring, or control actions to perform.

Best Practices for Sensor Interfacing

- Stable Power Supply: Sensors require a stable voltage and current supply to function correctly. Ensuring that you are using proper voltage regulators and capacitors to smooth out any fluctuations is a best practice. For battery-powered systems, consider implementing low-power modes or energy-efficient sensors.

- Regular Calibration: Over time, sensors may experience drift due to environmental factors. Regular calibration ensures accurate measurements and helps achieve error free readings.

- Use of Pull-Up or Pull-Down Resistors: In digital sensor interfacing, ensure pull-up or pull-down resistors are used appropriately to maintain stable logic levels.

- Efficient Data Acquisition and Sampling: Use appropriate sampling rates to capture data accurately without overwhelming the system as over-sampling, even though they can improve signal quality, it may lead to overuse of processing power.

- Testing and Validation: Before deploying your sensor system, thoroughly test it under various operating conditions. This helps identify potential failures or inaccuracies early.

FAQS

1. Why do I get inconsistent readings from my sensor

Ans. This is a common troubleshooting question. This problem might be caused by various factors, including:

- Presence of noise

- Insufficient sampling rate

- Environmental factors

- Sensor saturation

- Sensor drift

- Incorrect wiring

- Power supply fluctuations

- Insufficient data filtering

2. How do I choose the right ADC resolution for my sensor?

Ans. You can choose the right ADC resolution by considering these factors:

- Sensor accuracy and signal range

- System bandwidth and sampling rate

- SNR

- Application (Medium-resolution is well suited for general-purpose applications where whereas high resolution is well-suited for high-accuracy applications and precision measurements)

3. Can I connect any sensor to any microcontroller?

Ans. This is a common assumption that we can connect any sensor with any microcontroller, however, that’s not the case!

One must make sure the following criteria while interfacing a sensor with a microcontroller

- Voltage compatibility

- Current requirements

- Communication protocol compatibility

- Signal type

- Data transfer rate

- Number of available GPIO pins on the microcontroller

4. When should I use SPI/ I2C/ UART for sensor interfacing?

Ans. SPI:

- Use for high-speed sensor applications (accelerometers, gyroscopes, etc.)

- For sensors requiring high-speed data transfer

I2C:

- Generally used for low-speed sensors (Temperature, humidity, environment monitoring, etc)

- Applications with multiple sensors on the same bus

UART:

- For simple sensors with a low data transfer rate

- For asynchronous application requirements

So, in general, choose the protocol in such a way that it is compatible with the microcontroller and can balance the speed, complexity and cost.